Finland has been in the vanguard in adopting building information modeling (BIM) for infrastructure construction. In this interview I discuss with Teemu Kivimäki, CEO of DCS Finland, how Infrakit helps in projects that use BIM.

Can you say a few words about the background of your company and how Infrakit came about?

The background of DCS Finland (short for Digital Construction Solutions Finland) is in research done in University of Oulu where I worked as a research scientist on construction automation from 2007 to 2010. We were doing research with big infrastructure construction companies, exploring ways to improve worksite management and data flow.

What are the challenges in using BIM on infrastructure construction projects?

Main challenge the industry is facing is changing existing work processes and training people to use new tools. The technology is ready.

Can you explain how Infrakit works in a construction project?

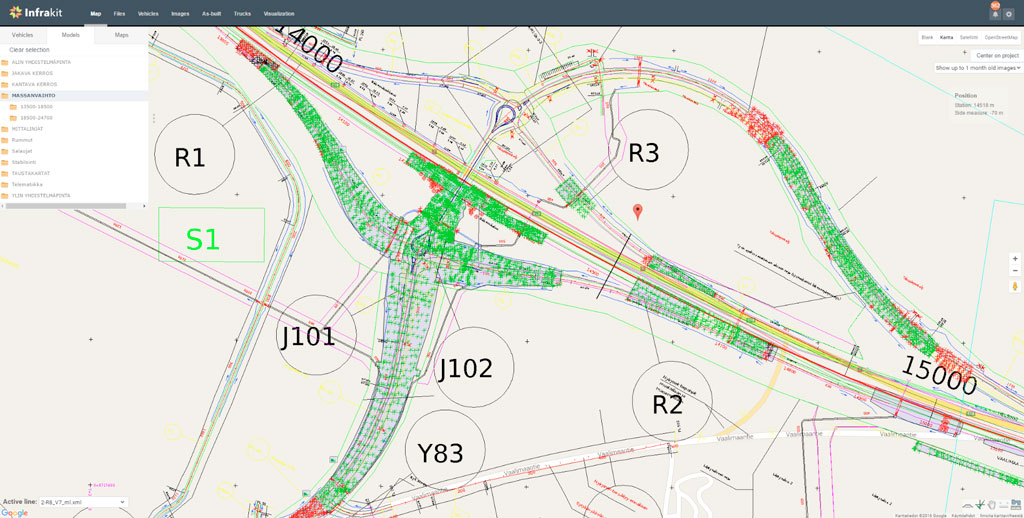

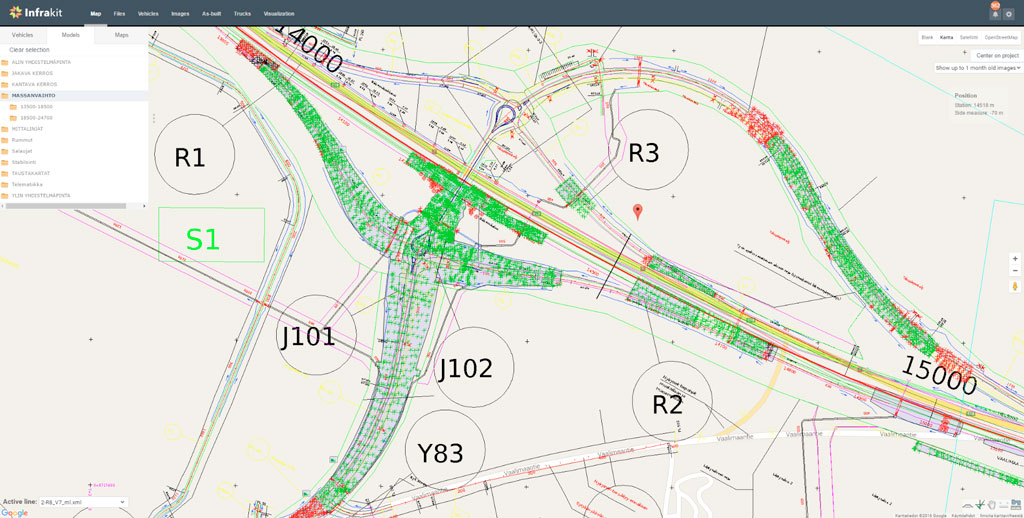

Infrakit is used to make construction projects digital. On a high level, 3D BIM designs are uploaded into the service and by connecting all work machinery and site personnel Infrakit can be used optimize implementation and eliminate construction mistakes by giving everyone access to the real time situation on site. By using Infrakit, everyone is connected. For example, excavators can see exactly when the next dump truck is arriving, all workers have access to all designs on tablet or smart phones, plus can see their own spot on top of the designs based on their GPS location. Infrakit also automatically makes sure you are building exactly what was designed and that there are no deviations from designed structural layers.

Who should use Infrakit and what benefits can they expect to get? Can you mention some examples?

Our main customers are construction companies and infra owners, such as cities and provinces.

According to our customers, real time situation report and quality information are a true game changer. For example, during construction phase, statistics indicate work machine efficiency going up as much as 40% when both Infrakit and machine control systems are adopted. This is because real time information and communication enables better planning and work management. For example machines don’t have to wait for surveyors to proceed with work. Any potential problems that arise on the field can be swiftly solved. Everyone has designs and location data at their disposal.

For infra owners, you end up with projects that simply cost less.You get a better quality end products and you reduce the risks of projects failing. You want to have a refined and complete designs for the tender phase as possible. With Infrakit, you can make sure you have procured designs that can be surely used during construction phase, in machine control systems, surveying equipment and quality reporting. You also get better overview on the construction work progress and quality. Traditionally, as-built quality reports can take up to six months to be completed. With Infrakit you get it on the same day, as a byproduct of the construction work.

You recently won a quality innovation award. What makes your solution innovative?

Infrakit is basically the embodiment of construction digitization. It’s binds together the rugged reality of infra sites and the eloquence of the digital world. The key is to make complex things such as BIM, coordinate systems and machine control, simple and easy to use. On a higher level, we have managed to hit something of a sweet spot, where tablets, mobile internet, machine control systems and BIM standards all come together.

How do you take Infrakit into use in a project?

You only need a web browser and an Infrakit account. We create a project for you and you upload your design. A simple design could be for example a DXF map of your project. When you are in the field you can see those designs and your own GPS location on top of them. This will help for example during tender planning. From example YIT used Infrakit during the tender phase of E18 Hamina-Vaalimaa and this helped them to win the 200 million euro tender. Now they are of course using Infrakit during construction (check our reference case for this project: https://infrakit.com/en/references/yit-e18-hamina-vaalimaa-motorway/ )

How do you see the future of BIM in infrastructure construction?

I see that in 2 to 3 years, all projects will use BIM and a cloud platform. The benefits of IT and digitization are just so massive that anyone not adopting these new tools will simply not win any project tenders. You wouldn’t win any projects today by using a shovel instead of an excavator. It’s a matter of using the best tools available for the job.

What are your company’s future plans?

Infrakit is aiming to be the global standard in digital infra construction data management. We believe that the future of the industry is networked systems and interoperability. Infrakit is a neutral ground, a communication BUS, for different hardware and software applications to work together and tap into the project designs.

Where can our readers find more information on your service?

Just go to infrakit.com! There you can for example find reference case studies on how our customers are using Infrakit.

Thank you for the interview, I am always happy to answer questions regarding Infrakit!

View the original article and our Inspiration here

Leave a Reply