The way we transfer data between organizations and systems has remained the same since the early days of the Internet. Planora, a Finnish company, has developed a radically new concept that simplifies communication, makes it safer, and saves IT costs considerably. I talked with Esa Teppo, the Managing Director, to learn more about the solution.

Planora is not one of those freshly minted startups that aspire to revolutionize construction. The company was founded in 1987 and has a long track record in municipal engineering, manufacturing, and automation design. Its latest discovery proves it has continued innovating.

The present state is both complicated and costly

The problem with our current way of information transfer and system integration is that it’s complicated, not always safe, and costly to maintain and develop.

As cloud computing becomes prevalent, communication and integrations depend on third-party services. Customer lock-in is an opportunity for service providers, but less favorable for the customer.

At the same time, the IT departments of large organizations have to build and maintain system integrations, support various user environments, and constantly fight against cyber-attacks.

Ultimate standardization is impossible

A construction project adds to the complexity of IT management. The composition of companies changes from project to project, and making reliable data exchange work between the participants is hard. The industry is trying to solve the problem with data model standardization, but Teppo does not believe that’s a working solution.

“You can’t standardize the future, especially the ICT sector that is constantly changing,” Teppo says. “There are built environment projects that try to standardize data. Some national organizations want to define data ownership externally to your IT system. I don’t think that’s feasible.”

Planora’s solution, called GreenBox, is built on the idea that users take control of their data and data ownership. In their model, communication between users and systems is not dependent on large tech companies and intermediaries.

GreenBox: Data Objects and Data Seas

The basic unit of GreenBox is a Data Object, an encrypted package of information that users exchange with each other. “It contains defined data in an undefined format, something that a traditional database can’t handle,” Teppo explains.

In computer programming terms, the content of a Data Object is defined using S-expressions. This allows the presentation of data free of predefined formats or standards.

A Data Object can contain selected data from applications or databases users want to share. The GreenBox messages are compatible with any IT applications. The Data Object contains ownership and access rights information, so you don’t need third parties to manage the exchange.

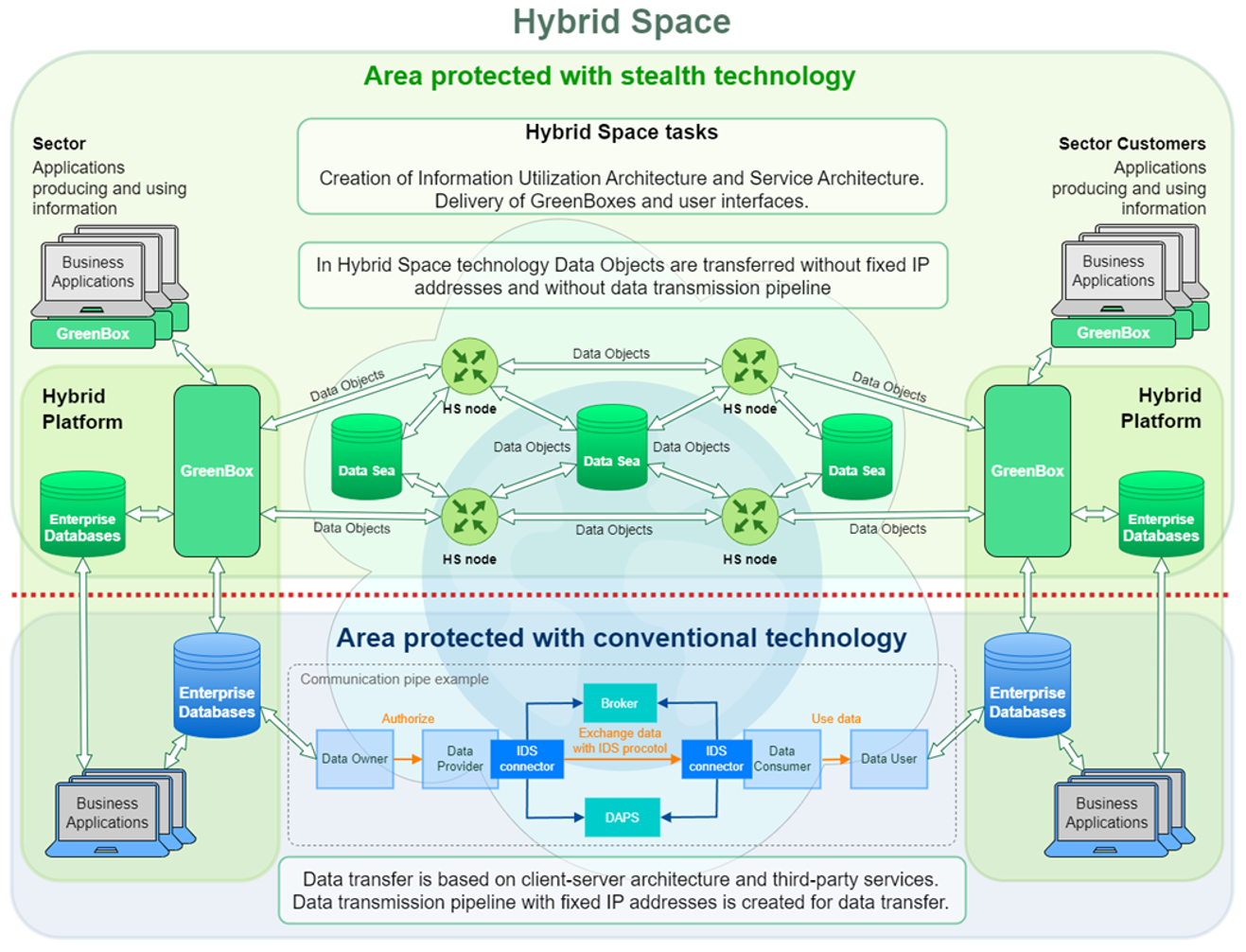

Data Seas are distributed pools of Data Objects. Users exchange Data Objects using so-called Hybrid Space nodes that connect users and Data Seas.

Teppo says the GreenBox system is built on well-known principles and technologies, but the company has patented its Hybrid Space technology. At the solution’s core is the Blockchain, but without the heavy mining operations required for cryptocurrencies.

The implementation

GreenBox is software installed on your computer, most IoT units, or the user company’s Hybrid Platform that connects to enterprise databases. GreenBox handles encryption and packaging of the information and saves Data Objects to Data Seas.

Like other Blockchain solutions, Data Seas are distributed among various computers. The seas can reside within an organization’s internal network if required. In any case, the data in Data Objects is encrypted and safe from hackers. As GreenBox is the organization’s data interface with the Internet, it also protects from intruders.

Planora further promises other benefits besides superior cybersecurity and interoperability. They claim GreenBox reduces ICT hardware costs by 40 to 70 percent, thus cutting down respective energy consumption by up to 50%. Thanks to GreenBox, a company needs radically fewer ICT professionals than previously.

The way forward

Teppo suggests two first uses for GreenBox in construction: IoT data transfer and supply chain management.

The number of IoT sensors and other devices is exploding, and GreenBox is an efficient solution for vendor-independent data exchange. Furthermore, the whole supply chain could use GreenBox to exchange data efficiently, automatically, and securely during a construction project. The implementation would be fast, and the benefits would be immediate.

Teppo points out that the development of GreenBox has continued for 20 years. It started when Mikko Paavola, the programmer at Planora, built a data object-based supply chain management system for Nokia’s network production. Nokia’s 150 providers used it to automate the management of production and delivery of component orders.

The development of GreenBox is based on functional programming. There are no “new versions”; new functions are added as needed without changing the previous code.

“Next, we need to develop user interfaces. For that, we need funding and customers,” says Teppo. “We have many patents in the pipeline, but before we move on with them, this core concept needs to be put into motion.”

View the original article and our Inspiration here

Leave a Reply