Imagine a construction site where every tool and piece of machinery is state-of-the-art, designed to make tasks faster and easier. Yet, the workers spend more time figuring out how to use the tools and searching for information than building. Welcome to the paradox of digitalization: the promise of efficiency turned into the reality of Gray Work.

Quickbase, the dynamic work management platform company, conducted the second Gray Work survey in the spring of 2024. It polled nearly 2,000 decision-makers from organizations in the United States, the UK, and Ireland. Among the respondents, 302 individuals (15.7%) were from the construction industry.

One of the key findings in the Gray Work Index report is that 37% of construction respondents believe their software solutions don’t meaningfully impact productivity. In fact, 43% claim that manual work has increased compared to a year ago.

According to McKinsey, AEC companies typically spend one to two percent of revenues on IT, which is still less than the average of 3-5% across industries. However, I foresee the percentage increasing in the coming years as companies try to achieve better productivity through automation.

Quickbase found that respondents to their 2023 research survey collectively used 77 different platforms and solutions to complete their work. My empirical data points to even higher numbers; for example, over 200 in just one mid-sized engineering firm.

Many of the upcoming IT investments will probably focus on artificial intelligence applications.

In the 2024 survey, 92% of respondents were curious about AI-powered tools that can potentially enhance productivity and efficiency. They already have many alternatives; Stepan Mikulic’s AI Hub lists over one thousand AI tools related to AEC.

Less time to be productive

So, it seems that the claim of construction lagging in digitalization will soon be obsolete. But are we seeing its expected benefits for increased investments in digital tools?

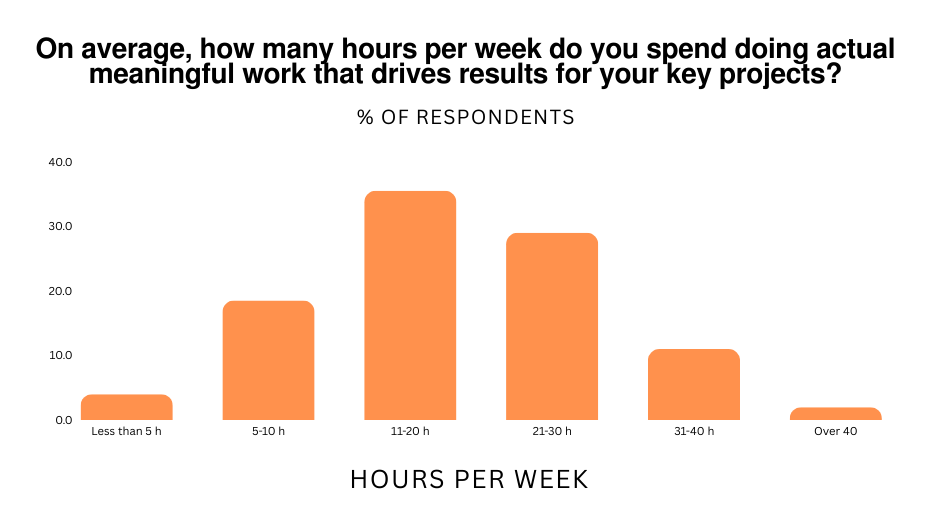

54% of Quickbase’s study respondents in the United States and the United Kingdom say it’s harder than ever to be productive and create meaningful value in their daily work. 58% claim they spend less than 20 hours on meaningful work that drives results.

A big part of that frustration results from using digital tools. Nine out of ten respondents report being somewhat overwhelmed by the number of software solutions they use daily.

An even more critical problem than the abundance of tools is that they are unconnected. Your finance data resides in one location, project data in several apps, and employee and supplier data are spread among several systems.

As a result, people manage and transfer data manually between systems—work that technology should do automatically. This leads to breaks in communication, rework, and errors.

Quickbase CEO Ed Jennings refers to the current situation as “productivity theater”—the work that fills our day but doesn’t move the needle for our businesses.

Adopting the lean mindset

Technical remedies exist to improve the current digital conundrum. However, we also need a new mindset to guide us to more efficient and satisfactory work.

Lean construction has provided excellent results in the physical world; why not adopt the same ideas in digital workflows?

The goal of Lean is to generate value for the customer and project stakeholders as efficiently and safely as possible using the six tenets. The “customer” in Lean can be anyone to whom you provide information, services, or products, such as your co-worker, a trade partner, or the client.

Adopting the six Lean principles in digitalization could look something like this:

- Respect for people – let people do meaningful work that utilizes their talents.

- Generate value – understand what the project participants making a request need and provide that information efficiently to them.

- Eliminate waste, including excessive apps and manual operations.

- Focus on process flow – make sure everyone has the information they need when they need it to perform their tasks without delays.

- Continuous improvement – identify the sources of Gray Work, pay attention to employee concerns, and eliminate obstacles continuously.

- Optimize the whole – eliminate data and process silos and collaborate toward joint success.

I’m convinced that our chances of success increase when you align your technology investment with the six tenets.

Moving the focus to data

Construction is the most complex industry. We can systematize it to a certain degree, but its dynamic nature will prevail, and digitalization should adapt to this reality.

There are ways to connect people, locations, and processes without becoming overwhelmed by apps.

Instead of focusing on discrete applications, consider the data the processes need and how to provide it. Data and its quality are also essential to make AI reliable.

Consider replacing unconnected apps with a platform that makes data readily available securely through a single source of truth. By adopting an integrated platform like Quickbase, which seamlessly connects workflows and data, construction companies can harness the true potential of digitalization, ensuring efficiency without the chaos.

Read the report

To understand the challenges of digitalization, I recommend downloading the Gray Work Index 2024 on our partner Quickbase’s website. Compare the results with your organization’s experiences and see if you need to reconsider how you invest in digital tools.

Also, listen to my interview with the company’s CMO, Eric Olson, to learn about his thoughts on the report’s results and the future of no-code development.

Photo: Aarni Heiskanen, 2024

View the original article and our Inspiration here

Leave a Reply