The construction industry is notorious for its complex supply chains and inefficiencies. But what if there was a way to make the entire process more transparent, efficient, and error-free? Enter BETK, a trailblazing Finnish project that aims to digitize the concrete element delivery chain. I talked with Teemu Alaluusua, the BETK project manager, who explained how this initiative will change the future of prefab.

The traditional concrete element supply chain

Practically every architect and structural engineer in Finland is familiar with panelized concrete construction, which has been used extensively since the 1960s.

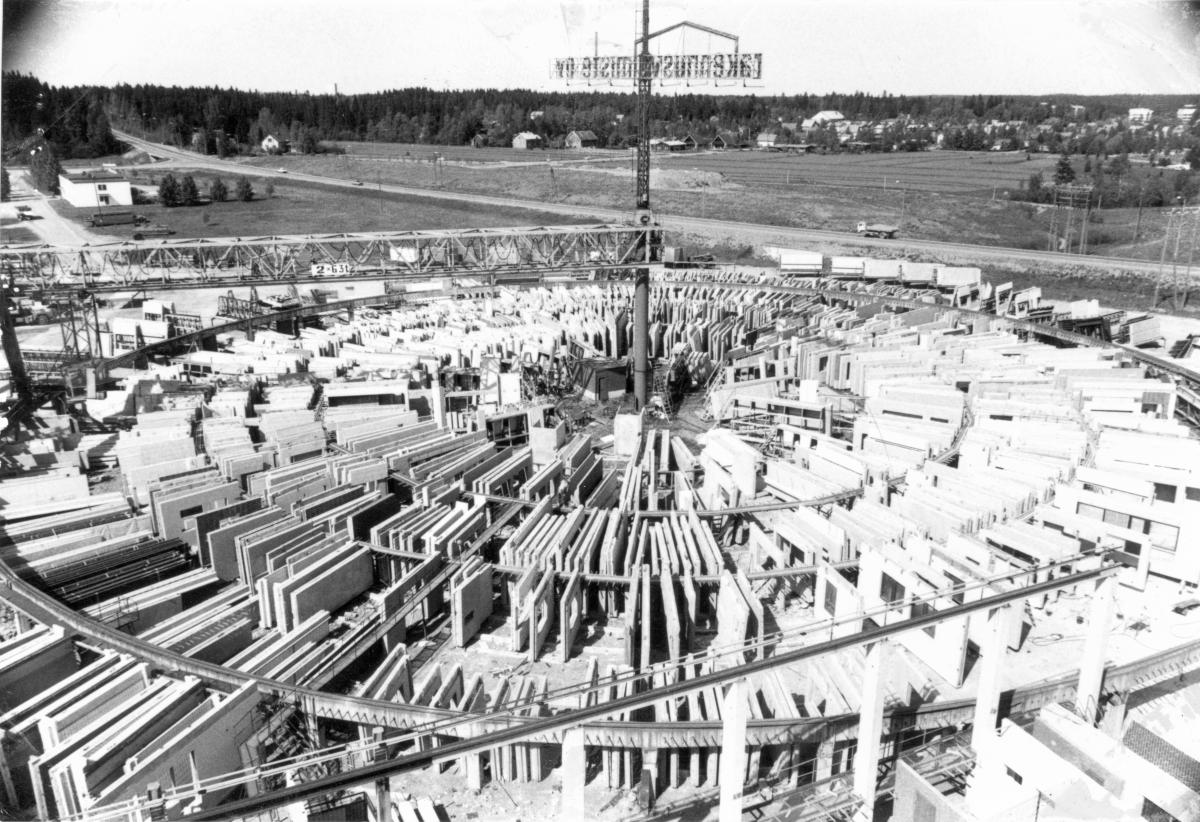

My first encounter with prefab was during my architectural studies in the early 1980s. I worked for a general contractor’s manufacturing company that produced elements for apartment buildings and single-family houses. Their element storage yard was impressive (Figure 1)!

Concrete elements are engineered to order, albeit using national standards. My company had an efficient but manual internal process for integrating design, manufacturing, and delivery.

Regardless of all the digitalization, the concrete element supply chain processes still depend on manual data management.

Lacking data management leads to inefficiencies

Teemu did his master’s thesis on digitalized supply chain management at Aalto University. He ran workshops that modeled processes and identified pain points and root causes of problems in current practices.

“We opened up the entire supply chain from design to lifecycle and studied the phases involved in the journey of a precast concrete element and what kind of information is shared and in what form,” says Teemu. “We started to think about what’s wrong, why the information doesn’t flow, and we identified the root causes quite well.”

The observations of the workshops and literature are pretty familiar to anyone who’s tried to digitalize supply chains.

The industry’s fragmentation makes coordination difficult, leading to inefficiencies and a lack of integration across the supply chain. Much of the data generated during construction is not systematically structured in a machine-readable format, making it difficult to manage, process, or share information with stakeholders.

Significant problems exist with communication and coordination among the various project participants. This leads to errors, delays, and additional costs, as issues are often only discovered later in the supply chain.

The thesis identifies the potential of using the GS1 supply chain management standard to improve the digital management of supply chain and product information. However, adopting such standards is rare, and the construction industry needs to catch up to other sectors.

The BETK project’s vision

BETK (Concrete Element Supply Chain) is a Finnish, innovative joint development project led by the Construction Industry RT. The 18 project partners include manufacturers, designers, software providers, academics, and information services firms.

BETK’s vision is an efficient, unified, transparent supply chain that utilizes modern digital solutions for information exchange, content management, and process harmonization. The project’s primary goal is to transition the concrete element supply chain from manual and unstructured information exchange to fully structured and machine-readable data exchange.

The BETK project includes five small working groups focusing on different aspects of digitalization: design data standardization, element identification, product and process data transfer, and the IT architecture and API description.

For example, the design information standardization group has used commercial software, Tekla Structures, to pilot-test new data specifications. The aim, however, is to make all the specifications software-independent.

BETK implements international standards

There’s no need to invent a new standard for concrete elements or other building products. GS1 is an international non-profit that provides unique identifiers for products in all industries. BETK has chosen to implement GS1’s standard for made-to-order products.

The minimum requirements for element identification data include

- A Global Trade Item Number (GTIN) for the product (similar to the barcodes in other products)

- A Made-to-Order (MTO) variation number

- A serial number

- Element marking (a national code)

- GUID (globally unique identifier) for IFC object identification

RFID tags and GS1 DataMatrices (a two-dimensional barcode) will be used to identify physical elements.

“When these RFID tags are read at the construction site’s gate, a system records the information that it has arrived. The logging event stores its location, who read it, and its status,” Teemu explains.

He emphasizes that the identification is valuable even after the construction is completed: “Somehow, these elements must be identifiable throughout their lifecycle. And if such RFID tags can be embedded within the element, then it can be said to be almost eternally traceable.”

BETK proposes using the open standard IFC to share BIM models, EPCIS for event messaging, and Peppol, the international e-procurement network, for transaction, product, and logistics data exchange. Finland’s public started using Peppol in 2024, so it’s a natural choice for the local construction sector.

BETK has shared experiences with Swedish and Norwegian counterparts. In Sweden, there’s a GS1 construction group, and in Norway, BEAst Supply 4.0 is a pilot project that uses GTIN and Peppol to digitalize construction business processes.

The rollout

BETK will release its results in several phases, starting in autumn 2024. The group’s work will continue at least until the end of 2025. The resulting documents will be available in Finnish at https://betoni.com/rakentaminen/betk/.

Teemu believes that companies that start using BETK’s results will gain a competitive advantage from enhanced efficiency and accuracy. He also predicts that once the BETK project has provided valuable results, a similar project for mass timber construction will be on the horizon.

You can connect with Teemu on LinkedIn.

View the original article and our Inspiration here

Leave a Reply