I sat down with Robert Salaj, the director of the Customer Advisory Team at Quickbase, to discuss how construction companies can successfully digitalize their business processes. Robert shared insights from his extensive 20+ year career in lean Six Sigma process improvement and his decade-long experience in the construction industry.

The industry faces several pressing challenges, including labor shortages, supply chain disruptions, and fluctuating interest rates. Speeding up construction and improving its productivity without compromising quality is becoming increasingly critical.

Back to basics

Companies are looking for digitalization as a solution but are often disappointed with the results. That’s mainly because they try to fix each issue with a separate piece of software. The result is a mix of unconnected pieces in every project or within the same company.

“If you don’t have your data set correct in your architecture setup, you’re not going to get the right metrics at the end of the day. And quite frankly, you know what you’re going to do? You’re going to ruin morale,” Robert says.

Robert advocates a back-to-basics approach. He emphasized the need to establish a solid foundation of standard operating procedures before adopting new technologies. He also discussed integrating various systems to streamline workflows and improve data management.

Ten insights

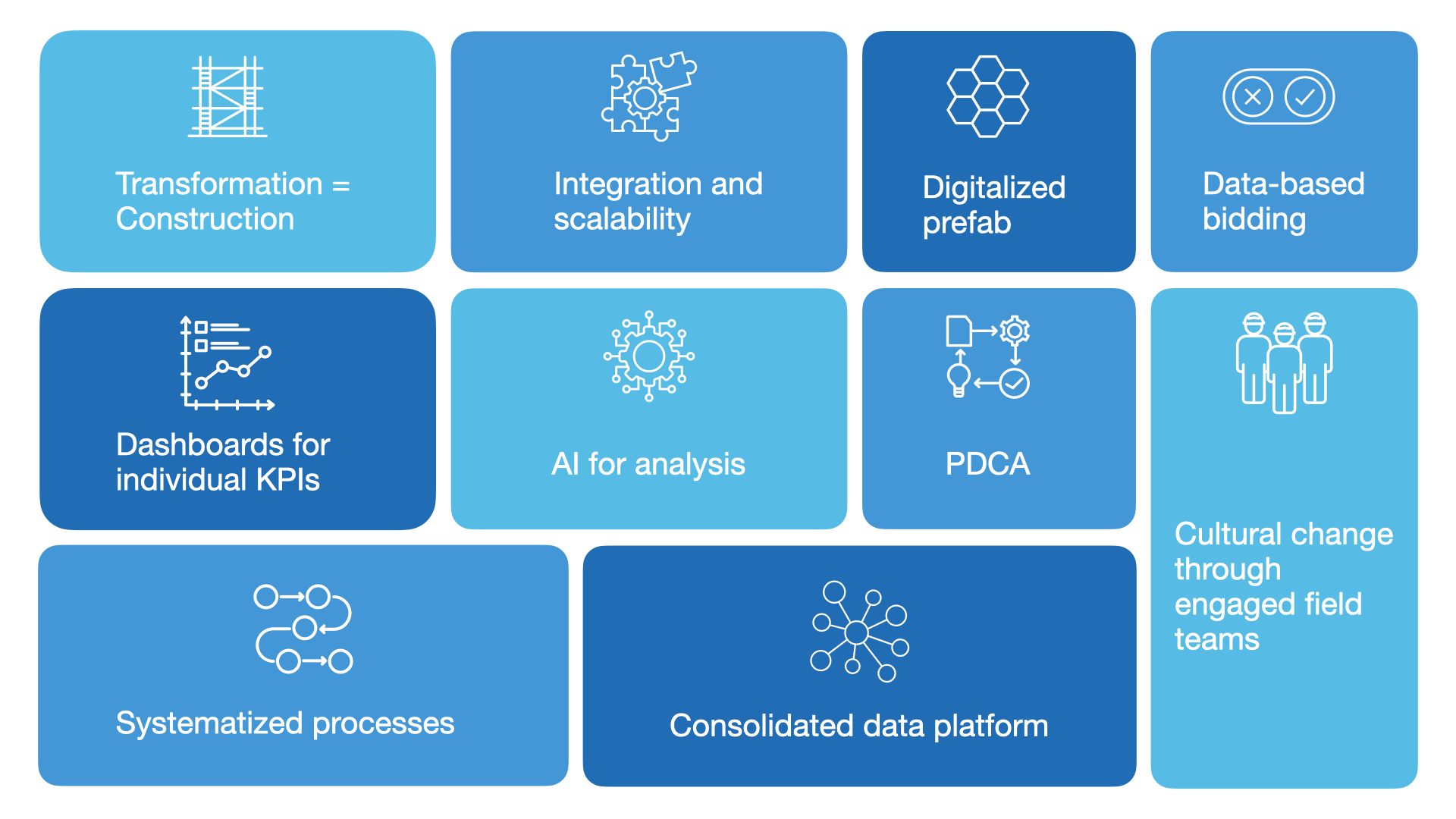

How, then, can you successfully start digitalizing your construction processes? Here are ten insights I picked from the interview:

- Establish clear, standardized processes, because digitalizing without systematization won’t improve your results.

- Consolidate data into a central, structured system. This enables seamless integration and data analytics.

- Engage field teams, such as foremen, in the development and planning stages to ensure buy-in and usability.

- Define clear KPIs for every role to measure progress and success and tailor dashboards to individual roles.

- Focus on tools and platforms that integrate well with existing systems. Invest in technologies that allow for scaling and adaptation, such as low-code platforms like Quickbase, which enable custom workflows and rapid development.

- Create feedback loops and apply Lean and Six Sigma principles, such as DMAIC (Define, Measure, Analyze, Improve, Control), to guide the transformation.

- Digitalize your bid management and make data-driven decisions on which projects to pursue.

- Enhance prefabrication workflows by connecting data across modeling, logistics, and field operations.

- Harness AI to analyze datasets for tasks like bid management, contract analysis, and workflow optimization.

- Treat digital transformation projects like construction projects and emphasize pre-planning and stakeholder involvement.

The ultimate purpose of digitalization

Many construction firms have chosen Quickbase as a data-centric, no-code, or low-code platform. Robert shared success stories of how Quickbase has led to notable improvements in bid management, prefabrication, safety, and more.

Whatever technology you choose, you should help those in the field in their daily work. As Robert put it:

“I think a lot of times we just overlook some of the simplicity, Aarni, overall. Like we’re looking at very complex stuff, but they just want to sit down and say, I need to know how many invoices I need to work on today. I need to know how many RFIs are open. What are the device submittal logs? […] And if you’re able to solve for that, I think it’s huge.”

View the original article and our Inspiration here

Leave a Reply