What is the moment of truth of a construction project? It is when an on-site worker enters the jobsite to start doing whatever they plan to do. It is the culmination of a long process that started years ago and the start of a process that will end decades from now.

That idea came to mind when I listened to a presentation by Otto Alhava, the CTO of Fira, a Finnish general contractor. He discussed how construction workers are typically not provided the means to do their work optimally. That’s why HVACE installation teams, for example, spend less than 20% of their time on-site on actual installation.

The product and material data challenges

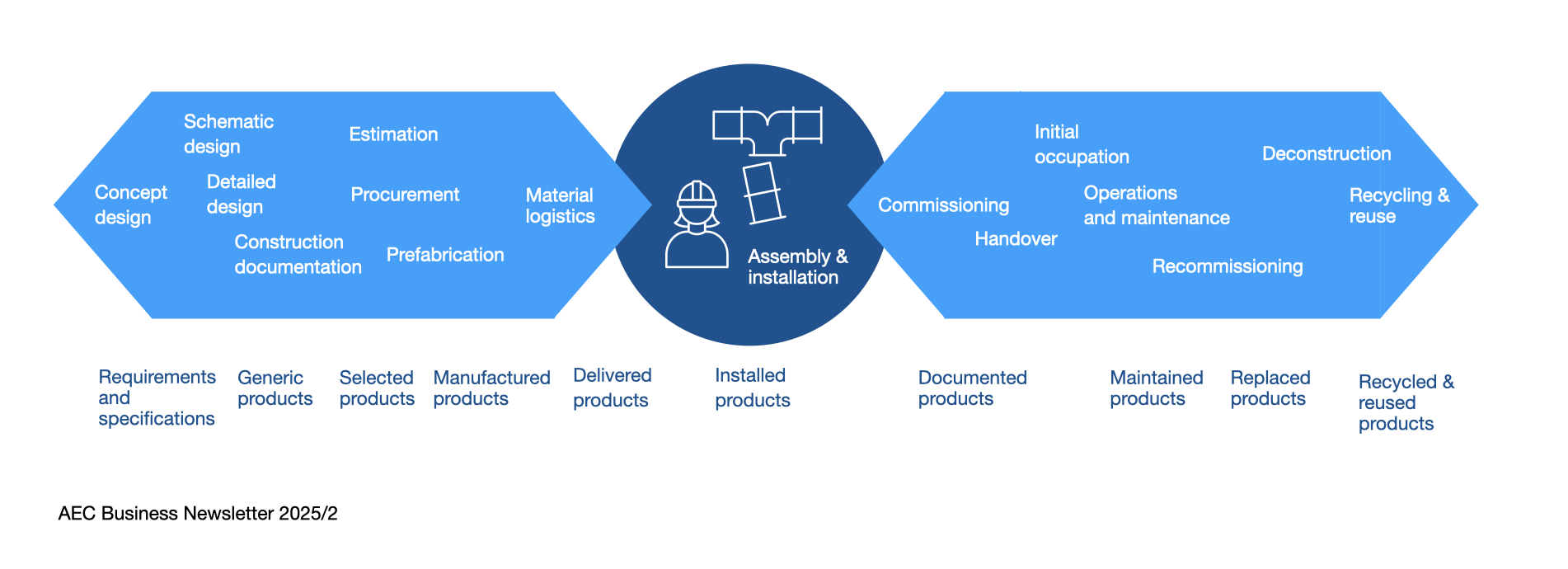

A critical component that Otto Alhava and other Finnish construction innovators talk about regarding productivity is product and material data flow throughout the design and construction processes. Today, the flow slows down or completely dries up several times over the project life cycle. A good example of this is how we use BIM.

Designers create models using BIM software but print out 2D PDF files from which contractors’ estimators do QTOs, maybe using an AI-powered tool that interprets the prints. They then create bills of materials for procurement, perhaps as Excel files. Retailers manually enter the same information into their systems. Finally, a logistics company delivers the products to the site, where they are stored and typically moved six times before they enter the location where they are installed.

The same product information is created and calculated at least six times. This is inefficient, but it also shows that the construction process is far behind how manufacturing companies manage product data.

Consequently, the installation workers must spend a disproportional amount of their workday on material hauling and management tasks. In addition, the material flow is not in sync with the schedule.

The solutions are there

Solutions for better product and material management are already available. The issue is not technology but agreement on processing and exchanging product and material data.

GS1 is an international non-profit that provides unique identifiers for manufacturers’ products. Examples of the available codes include GTIN (Global Trade Item Number), SGTIN (Serialized Global Trade Item Numbers), and SSCC (Serial Shipping Container Code).

PEPPOL, the Pan-European Public Procurement Online, provides the specifications to exchange invoicing, product, and logistics data.

Industrialization through information management

Implementing standards like GTIN and PEPPOL industry-wide will bring construction closer to an industrialized process. When designers, the construction site, and the whole supply chain are in sync, process efficiency will increase by double-digit percentages. The owners will also receive accurate as-built documentation that serves the life cycle of the building.

Another essential feature of systematized product data management is the ability to calculate accurate carbon footprints at any project stage. Product identifiers are key to manufacturers’ CO2 databases.

Agreeing on the systematic use of these standards is challenging, but the move from paper-based to electronic invoicing and the use of barcodes in retail serve as inspiring precedents. Software developers must naturally ensure their products enable an easy transition to new workflows.

The roadmap

In Finland, companies, academia, and the government are collaborating to digitalize the construction sector. On the industry’s roadmap, product data management is included in the first stage to improve the efficiency and transparency of existing processes.

The second stage focuses on making construction sustainable through lean methodologies, comprehensive carbon emission management, and AI-powered processes. The aim is to make construction an elemental part of the circular economy.

PS.

Whenever we discuss improvements that make construction more efficient, someone asks, who will benefit? If we invest in improved product data management, will we see an improvement in our bottom line, or is the value realized downstream? It’s a great question. The solution may be in revised agreements and incentives or altogether new business models. What do you think?

View the original article and our Inspiration here

Leave a Reply