The software developers CoreTechnologie and Phasio are entering into a ground-breaking partnership. Together, the specialists are introducing an automated solution for 3D printing technology users in the field of SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion).

CoreTechnologie, the developer of the universal 3D printing software 4D_Additive, and Phasio, the manufacturer of the calculation and workflow software solution specifically for 3D printing, are joining forces. The new partners are introducing an automated solution for users of SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) technologies.

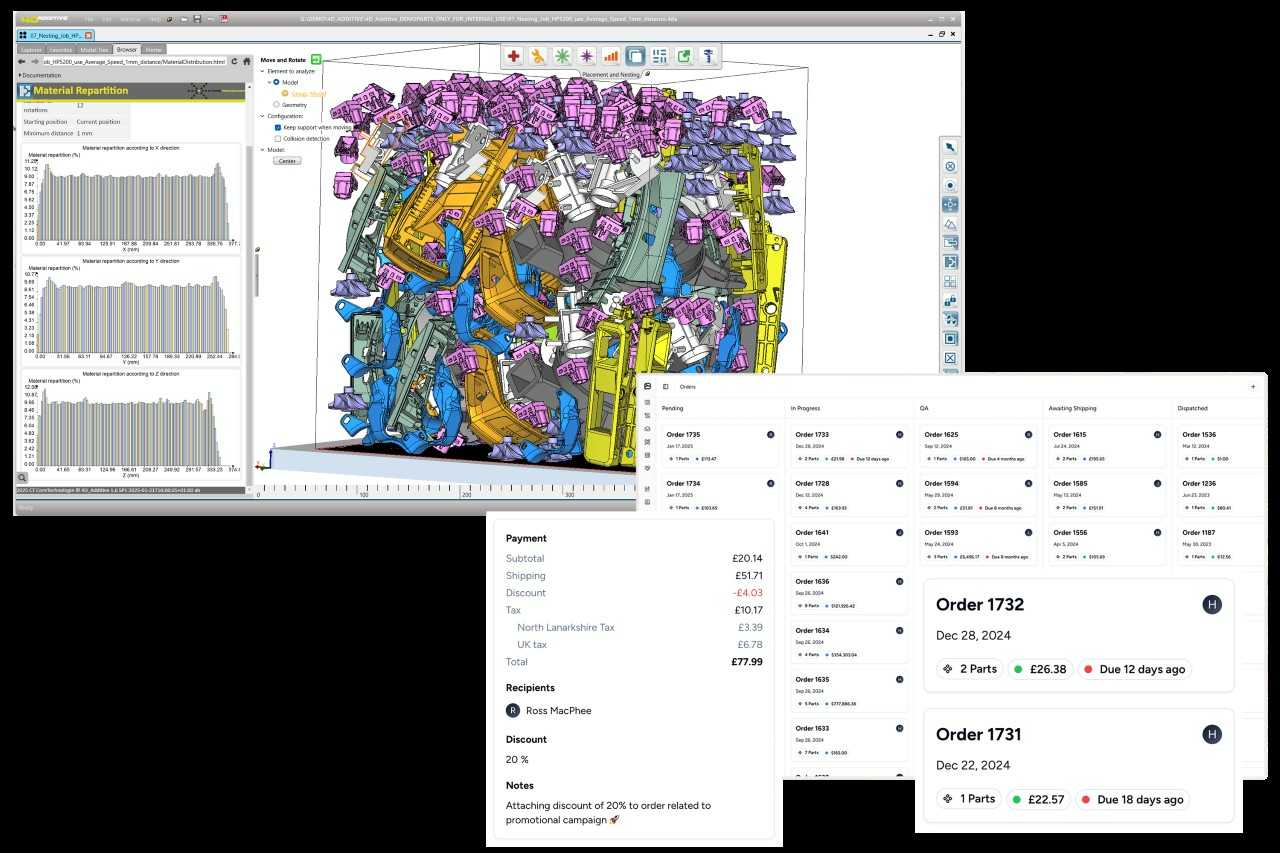

The integration of Phasio’s advanced software with CoreTechnologie’s 4D_Additive enables seamless, fully automated workflows in additive manufacturing. Production management, nesting and real-time updates are integrated into a single optimized process. The collaboration between the two software manufacturers increases efficiency, eliminates human error and accelerates the scaling of production processes, revolutionizing SLS and MJF workflows.

Advantages of the Integrated Solution

Phasio’s AI-powered platform enables fast and accurate quotation generation, optimized production planning and quality monitoring to simplify overall production management. 4D_Additive’s advanced, AI-based nesting tools ensure optimal utilization of machine capacity, saving time and resources. Real-time updates in Phasio minimize manual intervention, reduce errors and increase operational reliability.

Scalability for Additive Manufacturing

The integrated solution supports production companies in scaling their additive manufacturing while simultaneously optimizing cost efficiency and quality standards.

By combining the robust production management capabilities of Phasio and the innovative nesting capabilities of 4D_Additive, this partnership provides a sophisticated end-to-end solution for additive manufacturing facilities. This enables control over production processes while automating repetitive tasks. This saves time and process costs and ensures consistent quality and reliable data management throughout the entire workflow.

The collaboration between Phasio and CoreTechnologie creates new opportunities for innovation and scaling of additive manufacturing.

Further information on the software is available at www.coretechnologie.com/products/4d-additive.

Background Information CoreTechnologie

The software manufacturer CoreTechnologie (CT) was founded in 1998 and is headquartered in Germany near Frankfurt am Main with subsidiaries in France, Japan and the USA. The company is the leading provider of 3D Computer Aided Design (CAD) conversion software, known as 3D_Evolution™ (conversion, repair, simplification, analysis), 4D Additive™ (3D printing software suite), 3D_Analyzer™ (CAD viewer with analysis tools) and 3D_Kernel_IO (CAD Interfaces SDK). The company’s mission is to optimise MCAD interoperability in the design value chain and to develop customized solutions for PLM integration and process automation. CoreTechnologie’s customer portfolio includes over 600 internationally active companies worldwide from the automotive, aerospace, mechanical engineering and consumer goods industries as well as leading manufacturers of 3D software.

Background Information Phasio

Phasio is a global high-tech startup founded in 2021 and headquartered in Singapore. The company develops software for large-scale digital manufacturing production. Phasio develops advanced technologies that meet environmental sustainability and modern demands for cost and efficiency in manufacturing and global logistics. Phasio is funded by Airtree Ventures, 500 Global and Entrepreneur First.

Feature Image Courtesy of: Core Technologie Gmbh

View the original article and our Inspiration here

Leave a Reply