Tuomas Syrjänen’s keynote at the AI in AEC 2025 conference was a wake-up call. Drawing on his extensive experience in data science, consulting, and board service in the construction sector, he challenged the audience’s assumptions about the industry’s future.

Tuomas began his journey in data science in the 1990s, founded Futurice in 2000, and currently chairs its board.

Throughout his journey, he has learned that digital technologies achieve exceptional results only when combined with a redesign of processes, paradigms, and organizational culture. The same holds true for AI.

Putting new technology in front of a 100-year-old process

To kick off his talk, Tuomas showed a clip of MythBuster Adam Savage being pulled in a traditional rickshaw by Boston Dynamics’s Spot the Robot.

“We take the latest and the greatest technology, whether it’s AI or robots or whatever, and we put it in front of 100-year-old process, ways of working,” said Tuomas. “And then we are wondering, why don’t we get any results?”

This tendency isn’t unique to construction. Tuomas also referenced a law firm CEO who admitted their business hadn’t changed in 80 years, yet they were now trying to implement AI.

That doesn’t mean proofs of concept like Savage’s stunt aren’t useful. They help us understand the technology. However, real benefits arise only when we go further.

A paradigm shift

About a decade ago, construction companies Tuomas worked with started experimenting with technology only to realize that it didn’t make much of a difference.

They discovered that a true paradigm shift was necessary. That meant embracing principles of industrialized construction: breaking work into smaller units, increasing clock speed, identifying new KPIs, and more.

Tuomas shared some success stories, including a construction firm that cut cycle time from 16 to 9 months and saved €300,000 per site per month.

We’re shackled by yesterday’s constraints

Tuomas stated that yesterday’s constraints define the way we operate today. But with AI, many of those constraints no longer apply.

For example, you can deliver personal service without practically any extra cost. Or you can reduce process cycle time by 90% by eliminating handovers and manual compliance checks.

Tuomas urged the audience to challenge the assumptions they take for granted. Ask: “What if those constraints didn’t exist? How would we run our business?”

You need a full-stack view

We need full-stack thinking to achieve positive outcomes with technology; data and technology are just the foundation. To truly benefit, you must also rethink your processes, people, paradigms, culture, strategy, and business model.

The ultimate test is how technology helps people thrive.

Tuomas acknowledged that not every attempt had been a success. For instance, in one project, frontline workers were asked to report more to headquarters using a new digital tool. The goal was to provide management with real-time insights from the field.

But it failed because it added work for the field teams without helping them succeed, which is a dealbreaker for any change initiative.

What data?

AI is only as good as the data behind it. And in construction, the lack of structured, harmonized data is a big problem. Using AI on messy data isn’t efficient.

When we break down the construction process as in Takt production, work and material management become ten or more times more granular than traditionally. That’s when AI’s value really becomes evident.

Sometimes, it’s difficult to predict what data is valuable. Tuomas shared an insightful story about a company’s CFO who was frustrated because they couldn’t anticipate which sites would fail financially. The monthly site reports always appeared positive until the final month, when the failure was disclosed.

By coincidence, they discovered that access control gate data could predict a site’s success 6 to 9 months in advance. No AI required.

The key, Tuomas emphasized, is finding the right proxy data.

AI in construction: The buzz does not materialize

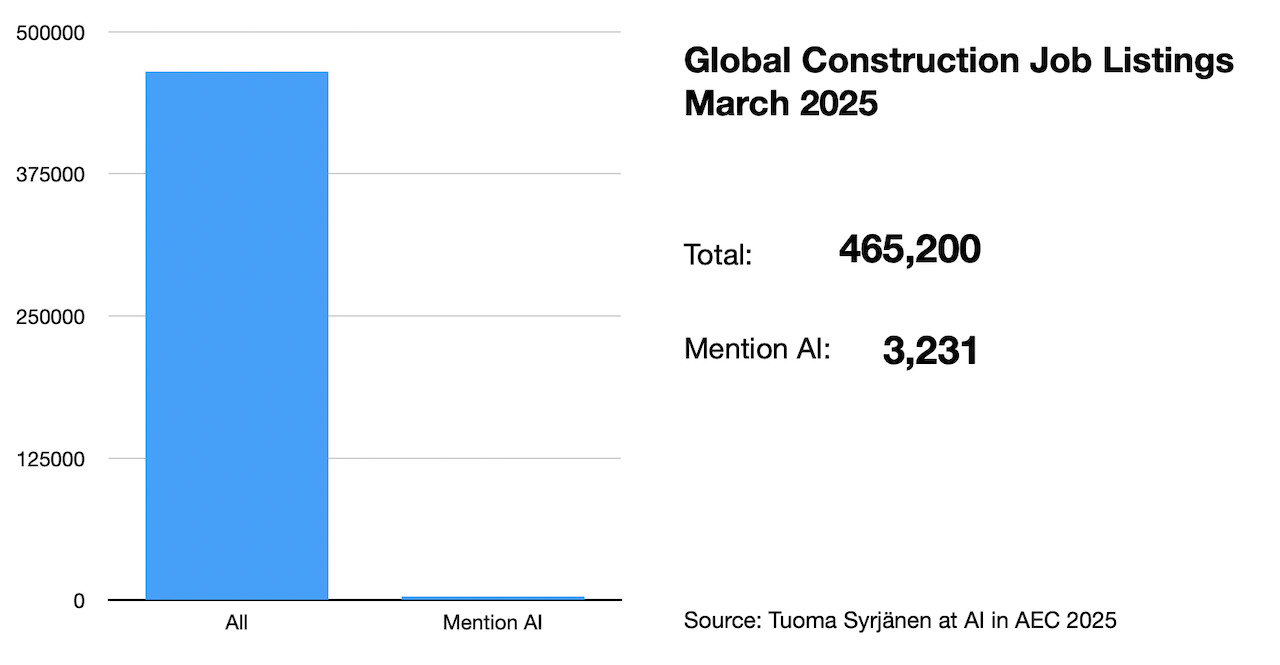

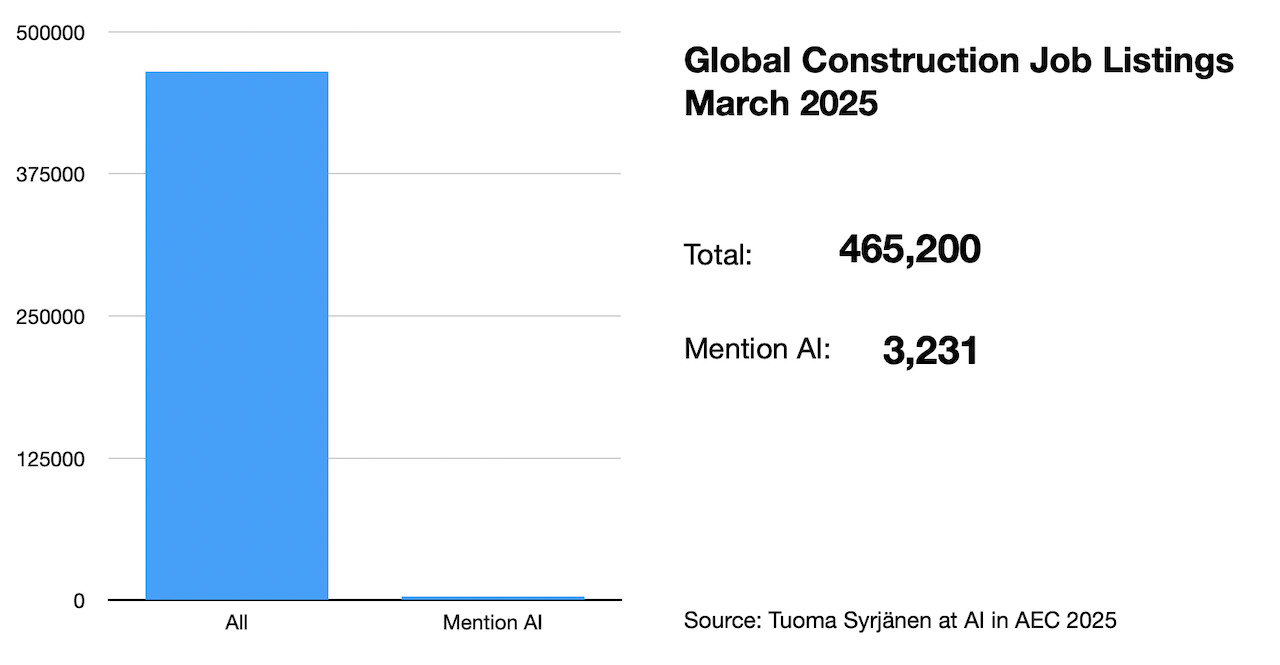

Tuomas shared another example of what data can reveal. He said job listings are the most honest mirror of what’s happening inside organizations. Everything else is talk, marketing, or wishful thinking.

Tuomas had collected data from job ads in construction sector companies worldwide for this year and last. The results were revealing.

Of the 465,200 job listings, only 3,231 mentioned AI, representing a mere 0.7% of the total. Tuomas noted that this figure is now approximately 2% in other industries. I believe that’s not high, given the hype.

Key takeaways from Tuomas

Tuomas called on the audience to look beyond tools and start imagining what transformative change could look like:

- Increase clock speed tenfold – Manage by the day, not by the month.

- Increase granularity – Move from week-long packages to 2-hour work packages.

- Bundle and unbundle – Don’t just coordinate one site; manage ten at once, with the same team delivering repeatable micro-tasks across all sites.

- Connect the company – Eliminate silos.

- Utilize abundance – Realize that the cost of many tasks is approaching zero.

Your choice: Be AI-using or become AI-native

Most AEC firms today are AI-using, not AI-native. Tuomas explained the difference in my short interview with him after the keynote.

AI-using companies apply AI to existing processes, layering it on top of outdated systems. Think auto-drafting emails, for example.

AI-native firms, on the other hand, reinvent the process. They equip frontline teams with AI tools, eliminate non-value-adding activities, and design workflows that assume AI from the start. They don’t optimize; they transform.

The big question is: Will established AEC companies dare to become AI-native, or will new entrants, unburdened by legacy constraints, seize the 10x opportunity?

View the original article and our Inspiration here

Leave a Reply