The phrase “Mind the Gap,” famously introduced for London’s subway system in 1968, has become a universal warning to stay vigilant in potentially hazardous situations. Yet, food production facilities often overlook a critical “gap” of their own—one that hides in plain sight beneath their very feet.

Hard-to-reach areas, like spaces beneath grates or crevices of poorly designed drains, are notoriously difficult to clean effectively. These gaps provide a prime environment for harmful bacteria, such as listeria, that thrive in damp conditions. The problem is compounded by gaps between surface drains and surrounding concrete floors, common in aging or improperly constructed drainage systems. Once bacteria seep into porous concrete, even strong disinfectants like bleach cannot completely eradicate them, allowing contamination to persist and resurface.

Recent studies have revealed a startling fact – over 80% of positive bacterial tests in food and beverage plants can be traced back to drains and floor areas, making them significant hotspots for contamination. The food industry now faces increasing scrutiny and stricter regulations, highlighting the urgent need for a revolution in drain design and maintenance.

Drainage systems should be as fundamental and reliable as the pallet is to logistics – easy to use, simple to maintain, and seamlessly integrated into daily operations. Unfortunately, many facilities still rely on outdated systems that are difficult to clean and prone to clogging, posing serious risks to food safety and operational efficiency. Modern, state-of-the-art drainage systems offer advanced solutions built to reduce contamination risk while being more durable and easier to install, maintain, and clean. Faster, more efficient cleaning processes encourage workers to perform their tasks thoroughly and consistently, resulting in safer facilities, improved efficiency, and peace of mind for everyone involved.

Types of Drains

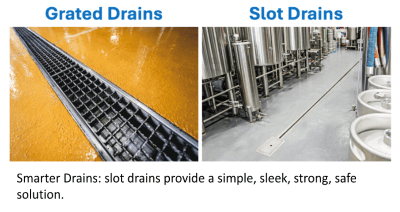

The right drainage system is essential for keeping food production facilities clean and efficient. Drains come in three primary types, each designed to address specific needs, including water flow management, hygiene maintenance, and accommodating varying levels of traffic. Traditional options, including area drains and grated drains, are adequate for some situations, but facilities that prioritize food safety and easy cleaning are increasingly turning to state-of-the-art slot drains.

● Area Drains: Suitable for smaller spaces like processing zones or equipment washdowns, area drains efficiently collect water, maintaining a safe and hygienic environment in compact areas.

● Grated Drains: Best for larger spaces like production floors or packaging lines, trench drains covered by metal grates handle high water flow and prevent pooling or flooding in high-capacity areas.

● Slot Drains: Known for durability and extremely easy cleaning, slot drains feature a narrow, grate-free design for a sleek appearance. Advanced models include specialized cleaning tools and clean-in-place (CIP) technology and heavy-duty construction, suitable for forklift traffic and aesthetically appealing customer-facing areas.

Modern slot drains are carefully engineered to align with how workers actually use them in real-world settings, encouraging best practices like thorough daily cleaning to ensure a safer, more hygienic environment. Simultaneously, they deter harmful behaviors, such as improper waste disposal, which can lead to clogged pipes and costly disruptions.

Making Drains Easy to Clean

In food production facilities, cleaning crews often struggle to properly clean drains—not necessarily due to negligence, but because the process can be excessively difficult or even impossible. So, what makes a drain truly easy to clean?

Accessible Design

First and foremost, the drain system must be accessible. In traditional area drain systems, about 95% of the system consists of pipes buried beneath the floor, rendering them inaccessible for clearing and cleaning. Unfortunately, bacteria don’t remain confined to these hidden pipes—they quickly spread to food production areas.

To make matters worse, these buried pipes tend to accumulate sludge and solids, leading to frequent clogs that often require professional cleaning services.

Traditional trench drains with removable metal grates may seem more accessible and easier to clean than the buried piping of area drains, but in practice, they introduce significant additional maintenance. The underside of the grates is notoriously difficult to clean, often harboring dirt and debris, which can lead to unsanitary conditions.

Moreover, these grates are typically heavy and cumbersome to remove, making routine cleaning a daunting task for cleaning crews. As a result, essential drain-cleaning procedures are overlooked or carried out inconsistently. Even when completed, the process can be highly time-consuming, often requiring several hours. In most cases, the area must be cordoned off during this time to ensure the safety of foot traffic and equipment, rendering the space unusable until the task is complete.

Slot drains offer a better solution. While they operate on the same gravity-based principle as the area drains system, they replace buried pipes with open channels that are immediately accessible without the hassle and burden of removing grates. This design allows for thorough cleaning, effective sanitizing, and easy clearing of debris, ensuring a more hygienic and reliable drainage system

Image Courtesy of: Global Drain Technologies

Specialized Cleaning Tools

Slot drains are not only more accessible for cleaning, but they facilitate extremely easy cleaning when matched with specially designed tools. Purpose-built tools that precisely fit the internal contours of slot drains easily glide along the channel, ensuring an efficient and thorough cleaning.

Food Safe Drains has become a leader in drainage innovation by closely observing how workers clean and maintain drainage systems in food and beverage facilities. In response, the company has developed a versatile range of specialized tools.

● The Paddle Tool: Perfect for quickly clearing debris from slot drains, this tool ensures an unobstructed drainage system.

● The Brush Tool: Designed for scrubbing the interior of drains, this tool effectively removes buildup. When combined with flushing or CIP (Clean-In-Place) systems, it delivers superior sanitation.

● The Slot Dog: A high-pressure cleaning tool that connects to water pressure systems and fits directly into slot drains, spraying along their length to deep clean the interior of the slot drain. It reduces cleaning time while keeping the surrounding area dry and hygienic.

● The Slot Hog™: This innovative attachment allows hoses to connect to slot drains at any point along their length. It provides a clean, efficient solution for transferring large volumes of liquid—whether from tanks or other sources—directly into the drain, eliminating spills and mess.

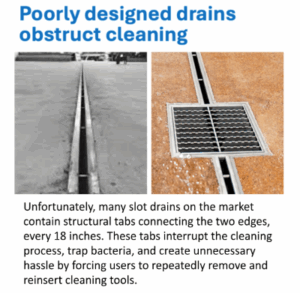

Unfortunately, not all slot drains are designed equally. Many slot drain systems include structural tabs spaced every 18 inches, creating obstacles that complicate cleaning and harbor bacteria. These obstructions make maintenance unnecessarily tedious by requiring constant removal and reinsertion of cleaning tools. In comparison, thoughtfully engineered slot drain systems feature a smooth, uninterrupted channel that allows cleaning tools to glide effortlessly along the entire length.

Built-In Cleaning Systems

In addition to portable tools, Food Safe Drains developed advanced built-in cleaning systems tailored to food and beverage facilities that require the highest levels of hygiene and efficiency:

● Flush Flo™ System: Connected to a water line, this system can be manually operated or set on a timer for automated cleaning. Simply open the valve to flush out the drain or automate the process for regular maintenance. It also dilutes high-temperature and caustic cleaning solutions, protecting downstream plumbing.

Image Courtesy of: Global Drain Technology

● Complete CIP (Clean-In-Place) System: This innovative solution allows the entire drain system to be sealed and filled with cleaning solutions. Unlike surface flushing or spraying, this method thoroughly sanitizes the drains, killing bacteria and removing built-up contaminants for optimal cleanliness.

Modern slot drains leverage smart design and advanced systems to surpass traditional area drains, grated drains, and older slot drain models. Engineered for food and beverage environments, they deliver superior cleanability and efficiency, setting a new standard in drainage solutions.

Making Drains Hard to Clog

Superior design isn’t just about making tasks easier—it’s about preventing problems before they occur. Food Safe Drains developed a Tamper-Proof Magnetic Strainer that exemplifies this principle. It addresses a common issue in traditional drain systems: workers improperly dispose of solids by dumping them into drains, leading to clogs, expensive maintenance, and potential contamination.

In conventional setups, removable strainers are often misused. Workers may dump the contents back into the drain instead of disposing of them properly or, in some cases, discard the entire strainer, leaving the system unprotected.

The Tamper-Proof Magnetic Strainer solution tackles this issue with an innovative secondary locking strainer. Positioned beneath the removable strainer, this locking mechanism can only be accessed with a special key. This design fundamentally changes worker behavior.

Without easy removal, workers are forced to maintain the system correctly. Attempting to bypass the process by removing the upper strainer reveals the locked secondary strainer, requiring manual debris removal piece by piece—an inconvenient and time-intensive task that workers naturally want to avoid. This discourages improper practices and ensures proper maintenance becomes the easier choice.

Moreover, the locked secondary strainer enhances accountability. Its presence makes improper handling of the system more visible to management. Workers can no longer dump strainer contents or discard the strainer without consequences, creating a transparent and enforceable maintenance process.

Empowering Your Cleaning Team

Modern slot drains offer an innovative and proven solution to elevate food safety in processing facilities. Designed to simplify cleaning procedures, they empower staff to work more effectively while upholding strict sanitation standards. By boosting operational efficiency and minimizing contamination risks, slot drains make a major contribution to maintaining food safety and optimizing facility performance.

Feature Image Courtesy of: Global Drain Technology

View the original article and our Inspiration here

Leave a Reply