How do you measure the performance of a takt construction project? That was one of the research themes presented at the Building 2030 summer seminar in Espoo, Finland.

The Finnish Building 2030 consortium held its summer seminar last Thursday and Friday. The event was the culmination of Building 2030 Week, which my company had helped organize for the fifth consecutive year.

During the week, Aalto University researchers and one from Tampere University, along with some of the 20 industry partners, attended panel discussions and gave presentations.

The Signe project in downtown Helsinki

One of the presentations was by Niklas Huitti, Project Manager, and Niko Ojala, Production Engineer, from Jatke. The Finnish contractor is delivering the Mannerheimintie 14 / Signe project, a 24,000-square-meter development slated for completion in 2026. Jatke’s client is Sponda, a real estate investor, the architect is Sarc, and one of the main users will be PricewaterhouseCoopers.

The inner-city location leaves virtually no room for storage, making logistics and scheduling particularly challenging. To tackle this, the project team has adopted takt production supported by an advanced digital toolchain.

“On-site, we have practically no storage capacity, so all materials are delivered just-in-time. The logistical challenges were a major reason why we chose takt production as well as the tight schedule,” Hutti explained.

From BIM models to takt schedules

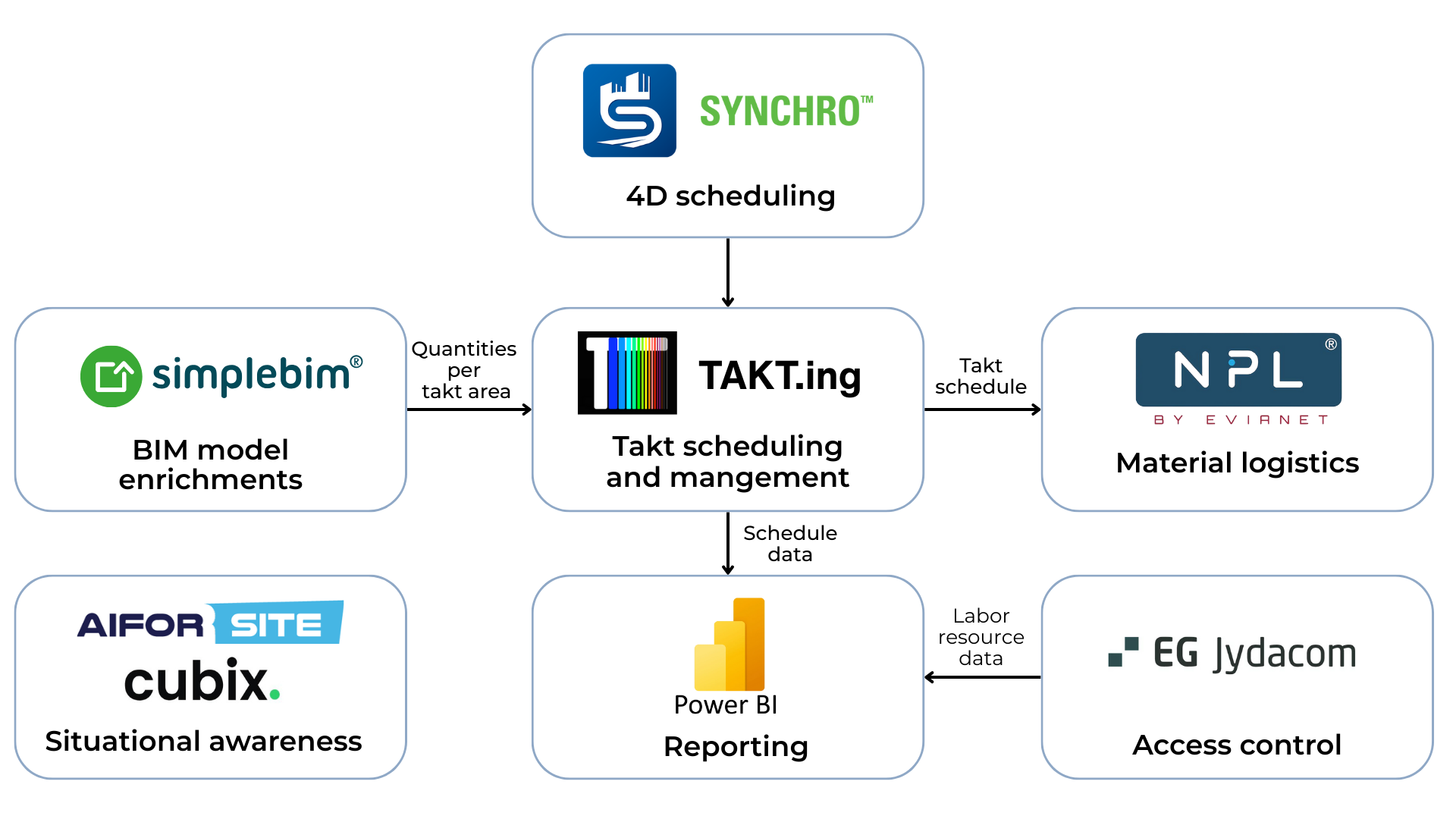

It takes a stack of software to plan and manage a takt project. Many projects still rely on Excel and manual data integration, but Jatke has taken it a step further.

The team relies on SimpleBIM Cloud to enrich designers’ BIM models with standardized data. Location prisms define takt zones, which are then linked to model objects.

Quantities derived from the enriched models feed directly into TAKT.ing, the takt scheduling and management software. This ensures every work package is tied to accurate, model-based quantities and locations.

Complementing this, Synchro was used for 4D scheduling in early phases, while MPL manages just-in-time logistics. Any changes in TAKT.ing automatically update the logistics system, ensuring delivery plans remain aligned with the evolving takt schedule.

Interactive scheduling and transparency

Within TAKT.ing, Jatke manages multiple work streams, from earthworks and foundations to structure and fit-out. Interior phases are broken down into takt areas of 200–300 m², typically on a half-week rhythm. Subcontractors can filter the schedule to view only their work packages, improving clarity and accountability.

Model-linked 2D/3D visualizations further enhance transparency, showing exactly which tasks are active in each zone at any given time. This helps contractors understand sequencing requirements and resource needs, reducing the risk of bottlenecks.

Digital site monitoring and reporting

Daily management is reinforced by digital progress tracking. Subcontractors update task status in TAKT.ing three times per week, marking work as not started, in progress, completed, or reporting disruptions. These updates flow into Power BI dashboards, which also integrate data from access control systems to compare planned versus actual labor resources.

Additional layers of oversight include remote-controlled Aiforsite cameras during structural works and Cubix for 360° photo-to-point-cloud conversion during fit-out. These tools support logistics planning, safety monitoring, and visual progress verification.

Clear rules and cultural shift

A “takt production rulebook” is attached to every subcontract agreement, ensuring that partners understand the principles and responsibilities from the outset.

While takt production is becoming more familiar in Finland, practices still vary between firms and projects. Jatke’s structured approach helps align expectations and fosters a shared culture of lean, predictable production.

Results so far

Thanks to digital-driven takt management, the team delivered the structure and roof slightly ahead of the general schedule.

Early test runs of interior takt flows helped verify logistics and sequencing before full production ramp-up, reducing risk later in the project.

To watch the panel discussions and presentations (in Finnish) during the Building 2030 week, visit https://building2030viikko.com/

View the original article and our Inspiration here

Leave a Reply