The construction industry embraces innovation to tackle some of its biggest challenges, like sustainability and labor shortages. A notable development in this area is the collaboration between ABB Robotics and the UK-based tech start-up AUAR, which focuses on using robotic micro-factories to build low-energy homes from timber.

AUAR reports that it has completed a £2.6M seed round led by deep-tech and AI fund Miles Ahead, alongside ABB Robotics & Automation Ventures and several other investors.

Innovating with Timber and Technology

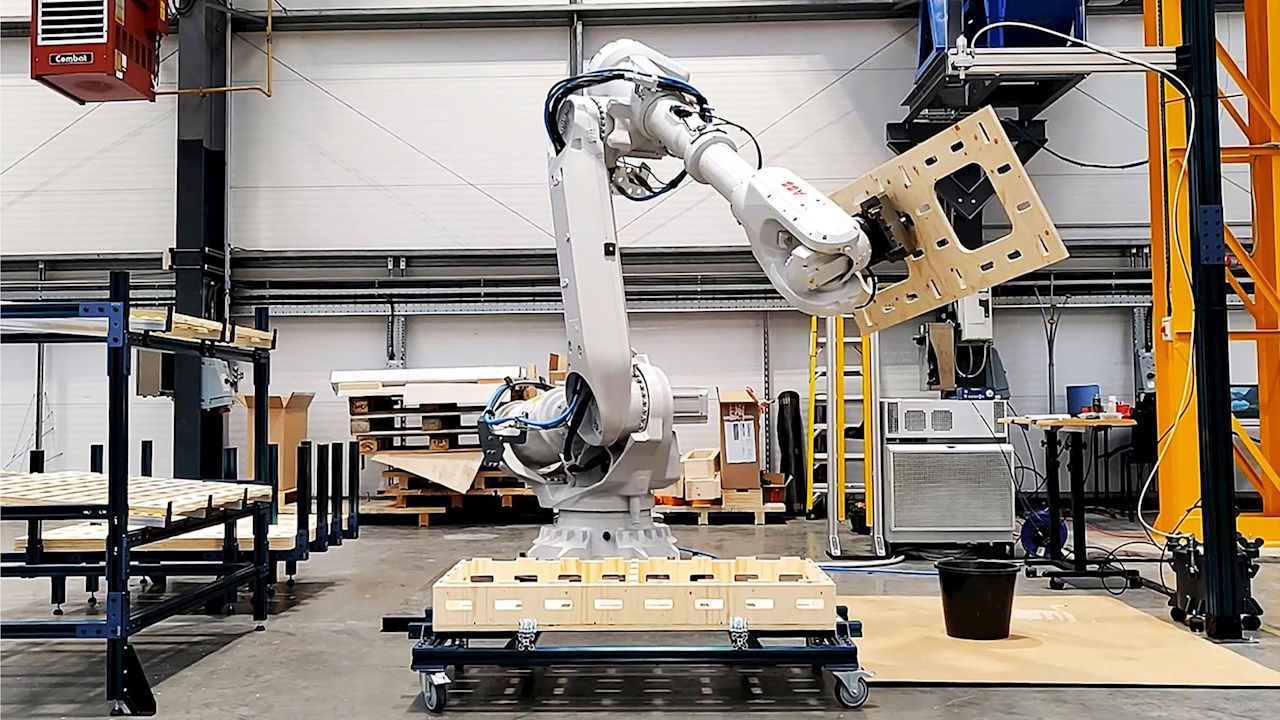

ABB Robotics and AUAR are working together to create affordable, sustainable homes using robots in micro-factories. These factories, strategically located near where homes are needed, use simple materials—just sheet timber—to streamline the entire building process. This method cuts down on waste and speeds up the construction of customized homes.

The production process uses standard sheets of timber. A robot cuts the sheets into components and assembles them into units transported to the site, enabling complete customized homes to be built in weeks.

Why Use Robots?

The construction industry widely acknowledges the need for sustainability, with 95% of firms emphasizing its importance.

Robots can play a significant role here, particularly in reducing waste. They bring precision and efficiency, cutting materials with accuracy and reducing excess. Moreover, robots are consistent and can work faster than human crews under certain conditions, which is crucial as demand for housing continues to grow.

Local Impact of Global Technology

The micro-factories are more than just production sites; they are part of a broader strategy to support local economies.

By building these factories near future home sites, the plan supports local jobs and reduces the logistical costs and environmental impact of transporting materials over long distances.

Collaborative Efforts and Future Prospects

AUAR isn’t working in isolation. Its founders, Mollie Claypool (CEO) and Gilles Retsin (CTO/Chief Architect), have engaged with ABB Robotics for over a decade and have seen significant advancements in robotics applications in construction.

Additionally, ABB’s ongoing work with firms like Porsche Consulting to develop new manufacturing practices in modular housing highlights a growing trend towards innovative construction methods that promise to make building homes quicker, less resource-intensive, and more accessible to a broader market.

A large movement

These initiatives are part of a larger movement towards using technology to address fundamental challenges in construction, from material waste to labor shortages.

By focusing on replicable technology and one type of material, ABB Robotics and AUAR are paving the way for more sustainable and efficient construction practices that could transform home building.

The relationship has already seen ABB Robotics win the Best Use of Robotics or Automation in Construction prize at the 2023 Robotics & Automation Awards.

Source: ABB, Zurich, Switzerland, 2024-03-20

View the original article and our Inspiration here

Leave a Reply