Industrialization is a crucial strategy for increasing the productivity and sustainability of construction. I sat down with Tomi Pitkäranta, Head of Concept and Partnerships at Sitedrive, to discuss how the company’s products help contractors systematize and industrialize production.

Sitedrive is a Finnish innovation. It originates from a 2016 internal startup competition of Fira Group, a progressive general contractor. In March 2022, the contracting company was split into two groups: Fira, a building contractor, and Flow Technologies, which includes Sitedrive.

Within Flow Technologies, Sitedrive develops digital services and solutions like software, data, and sensors. Its sister, Flow Modules, designs and manufactures intelligent building systems and bathroom modules.

“Our overall goal is to improve the flow of construction to achieve outstanding business performance,” says Pitkäranta. “On average, the workers are able to use only 20 % of their time to value-adding tasks. We aim to raise that to 80 %.”

Toward an industrialized process

Construction projects are an interplay between the client, general and trade contractors, manufacturers, and many other organizations. Unlike manufacturing, construction suffers from siloed organizations, disjointed processes, and poor process flow.

Each party optimizes its resource use and performance regardless of the needs of the others. This leads to inefficient projects, poor overall productivity, and constantly half-empty sites.

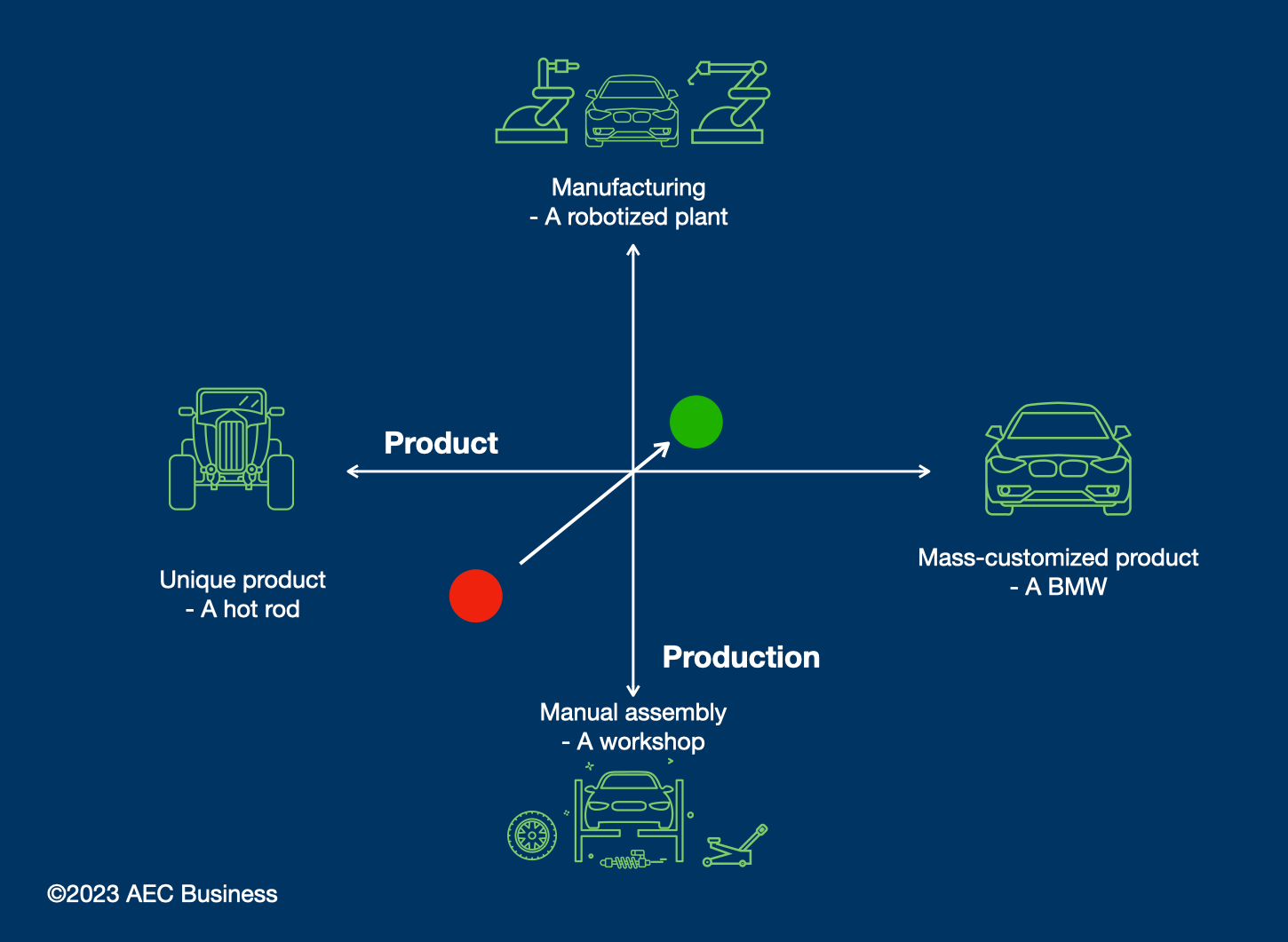

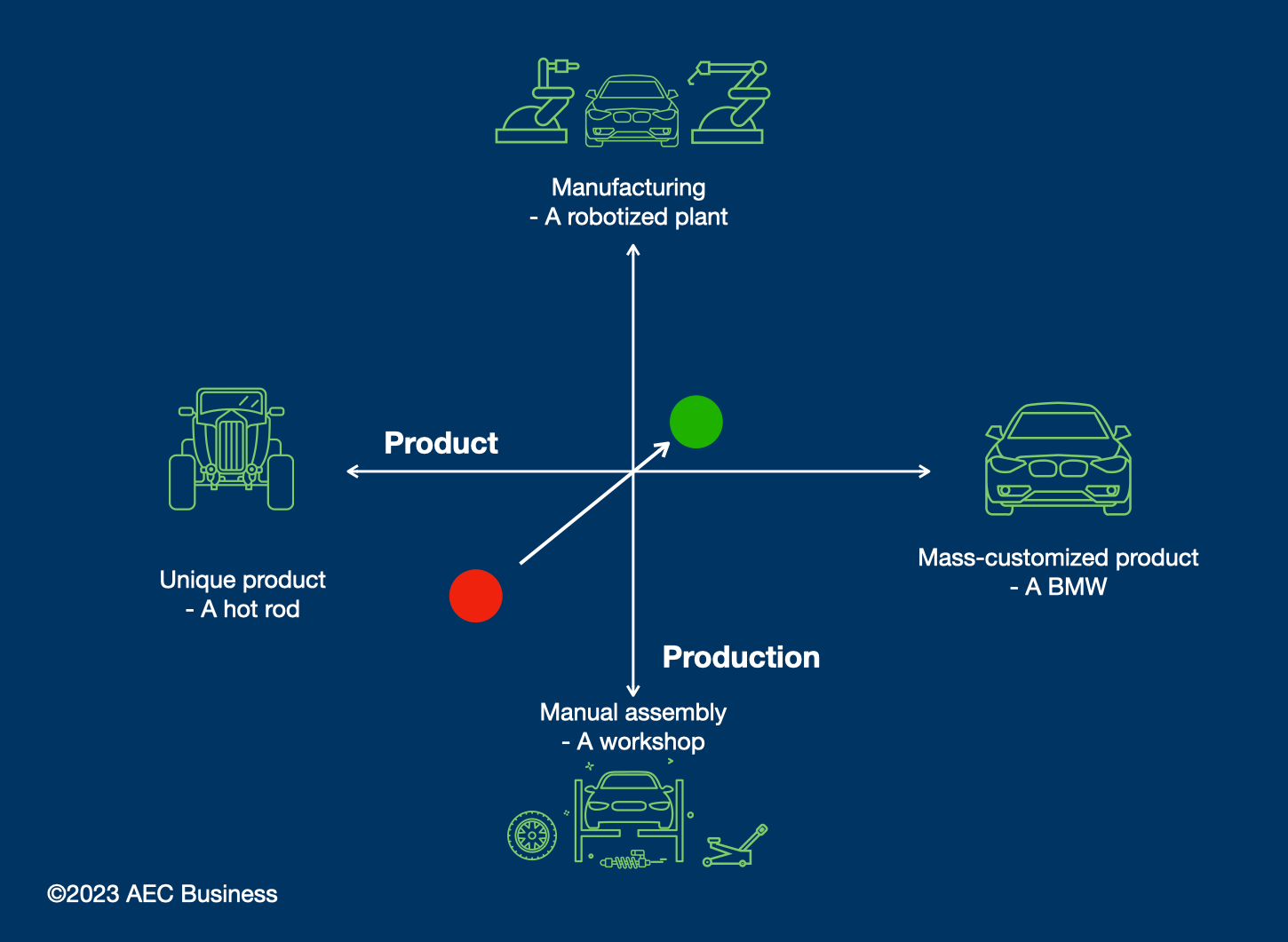

Construction firms are trying to take control of the building process by adopting ideas from manufacturing (Figure 1 Industrialization of production, a car-making analogy). They can industrialize their production by creating products rather than unique projects. A product can be, for example, an apartment building, a school, or a hotel. Developing products enables the standardization of solutions, using part kits, and improving the product continuously.

At the same time, contractors can move from a manual workshop process toward an on-site assembly. They can use prefabricated components and lean construction methods, like Takt production.

Fira has been keen on using Takt on their sites. One of their residential projects in Vantaa applies a model called Sitefactory, which is developed and operated by Flow Modules. It is a new management, scheduling, and logistics concept that builds on Takt principles. The Sitefactory enables a 40 – 60 % reduction of interior phase lead times depending on included work content.

Supporting industrialization with digitalization

With cloud-based and mobile tools, Sitedrive wants to improve the general contractor’s control over the building project. Sitedrive promises up to 50% faster construction flow when its processes and tools are used systematically.

Construction Execution System (CES) is a digital platform on which current and future tools of Sitedrive operate. It utilizes a standardized construction information data model that allows various applications to work together.

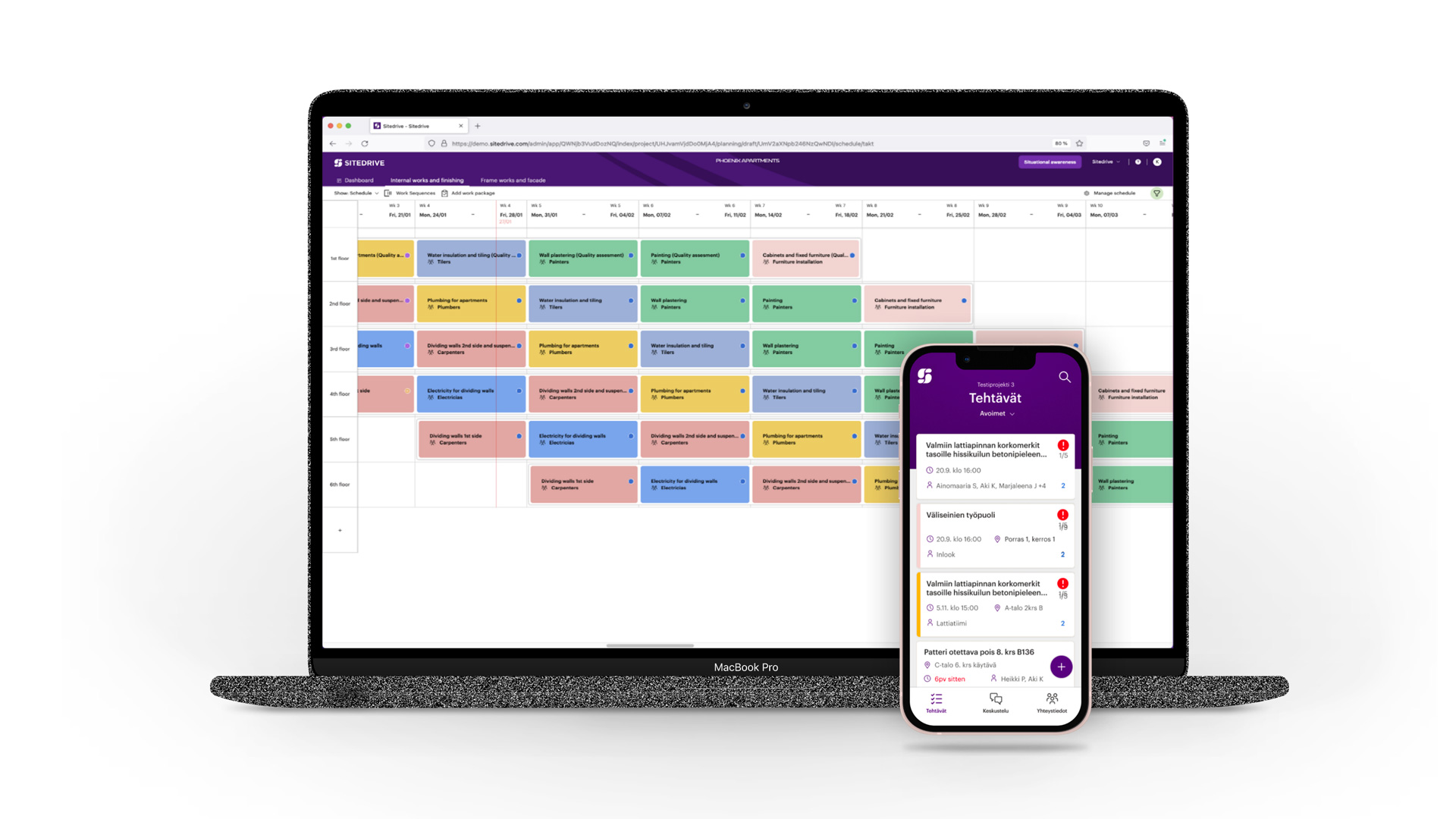

Sitedrive Schedule is software for collaborative scheduling for general and trade contractors and clients. Sitedrive Pay is the tool for approving, itemizing, and paying trade contractor invoices.

Sitedrive integrates with construction quality and safety software and uses sensors to capture the site’s humidity, temperature, and dust data.

“Building integrations case-by-case is time-consuming. That’s why we’ve partnered with certain sensor providers to speed up the process,” says Pitkäranta. “We’re also promoting common industry data models that allow frictionless interoperability between ecosystem partners’ solutions.”

Performance Indicators for predictive management

Leading with information requires you to have all the necessary data in real-time, not several weeks or months after you requested them, as is still typical in many projects.

Sitedrive 360 is a new addition to the product portfolio. It offers a comprehensive view of the construction project by combining data from enterprise systems with data from schedules and the site.

Another extension under development is the digital twin-based automatic scheduling and the quantity take-off, which are upcoming features as a result of merging Kulmakerroin solutions after the business acquisition.

The vision also includes the integration of the supply chain management functionalities into the platform. Ultimately, the feature will enable the linking of material kits to work packages resulting in just-in-time deliveries. These are currently being researched and developed with our technology partners.

Sitedrive provides both process and production performance indicators. Process metrics indicate how precisely an organization follows its predefined best practice. Production metrics forecast if the project will reach its schedule, cost, and Takt goals.

From scheduling to the daily and proactive management of work

A well-managed construction project starts with a general schedule, typically provided by the client. From there, the general contractor creates a location-based production schedule with Sitedrive. The GC shares the plan with trade contractors, who can modify or suggest changes if necessary.

To make scheduling easier, Sitedrive provides predefined work sequences. Contractors can also create standard operating procedure libraries themselves.

Once the schedule is completed, supervisors and teams manage daily work with a mobile app. It shows what tasks a worker or team should complete. The tasks have a schedule and location as well. Workers can report their progress and inform their managers about eventual obstacles to the job, like missing materials.

“The purpose is that the project has all the prerequisites in place for each task before their assembly starts. This way, we direct all the other flows to support the production flow,” Pitkäranta explains. “We envision capabilities that proactively alert about potential delays resulting from missing prerequisites. Consequently, we enable sites to solve problems before they affect the site performance.”

Implementing Sitedrive

Sitedrive has shifted its focus from selling a scheduling app to projects toward selling a solution to business owners and managers.

Pitkäranta talks about starting a change journey together with the client. It begins with understanding how they plan projects and manage work weekly. If switching to a Takt production makes sense for the client, Sitedrive offers training and support during the implementation.

Sitedrive has a project-based pricing model. The price depends on the project and client type.

The business’s future

In 2020, when Sitedrive was still in early development, there were just a handful of Takt planning software tools globally. Now there are dozens of them.

Pitkäranta emphasizes that Sitedrive has a contractor pedigree and productivity-focused R&D background. Remarkably, two contractors, Fira and Skanska, were involved in its development. Sitedrive’s value claims are also backed by peer-reviewed research. All this makes it stand out from the competition.

Sitedrive is strong in Finland and has clients in the Nordics, and it’s used in individual projects in several European countries. Systematic international growth is on the horizon but under certain conditions.

“Our solution creates the most value in countries like Finland, where the labor costs are high. With Sitedrive, you can increase labor productivity through improved planning and control. But to achieve significantly higher productivity, one must also increase the level of prefabrication. This can be achieved with Sitedrive’s and Flow Module’s complementary solutions,” Pitkäranta concludes.

Sitedrive is adding more features to its offering, hopefully remaining as user-friendly as it is today. Based on what I’ve seen and heard from the users, it is a noteworthy and agile competitor to many much heavier construction management solutions.

To learn more about Sitedrive, visit sitedrive.com.

View the original article and our Inspiration here

Leave a Reply