A team from the Faculty of Architecture of the University of Hong Kong (HKU) has developed a novel e-inspection system to monitor the manufacturing and delivery of student residence modules. It uses blockchain technology to store inspection records.

“This e-inspection 2.0 system is a world’s first. It has set new standards and will serve as a prototype for the industry,” said Professor Wilson Lu of the Department of Real Estate and Construction, who led the study. Other members included Dr. Frank Xue from the same Department, Professor Anthony Yeh from the Department of Urban Planning and Design, and Mr. KL Tam, Director of Estates.

A pilot project with 1,000 modular units

The HKU Wong Chuk Hang Student Residence is a pilot project built with Modular Integrated Construction (MiC) technology. The two 17-floor tower buildings have approximately 1,000 modular units (e.g., rooms and toilets), which will be manufactured offsite in a factory located in Guangdong Province. Inspected and qualified modular units are then transported to Hong Kong using containers via ships and trucks, and assembled at the construction site in Wong Chuk Hang.

The new MiC method substantially shortens construction time, addresses the problem of manpower shortage in Hong Kong, and reduces the environmental impacts of construction works.

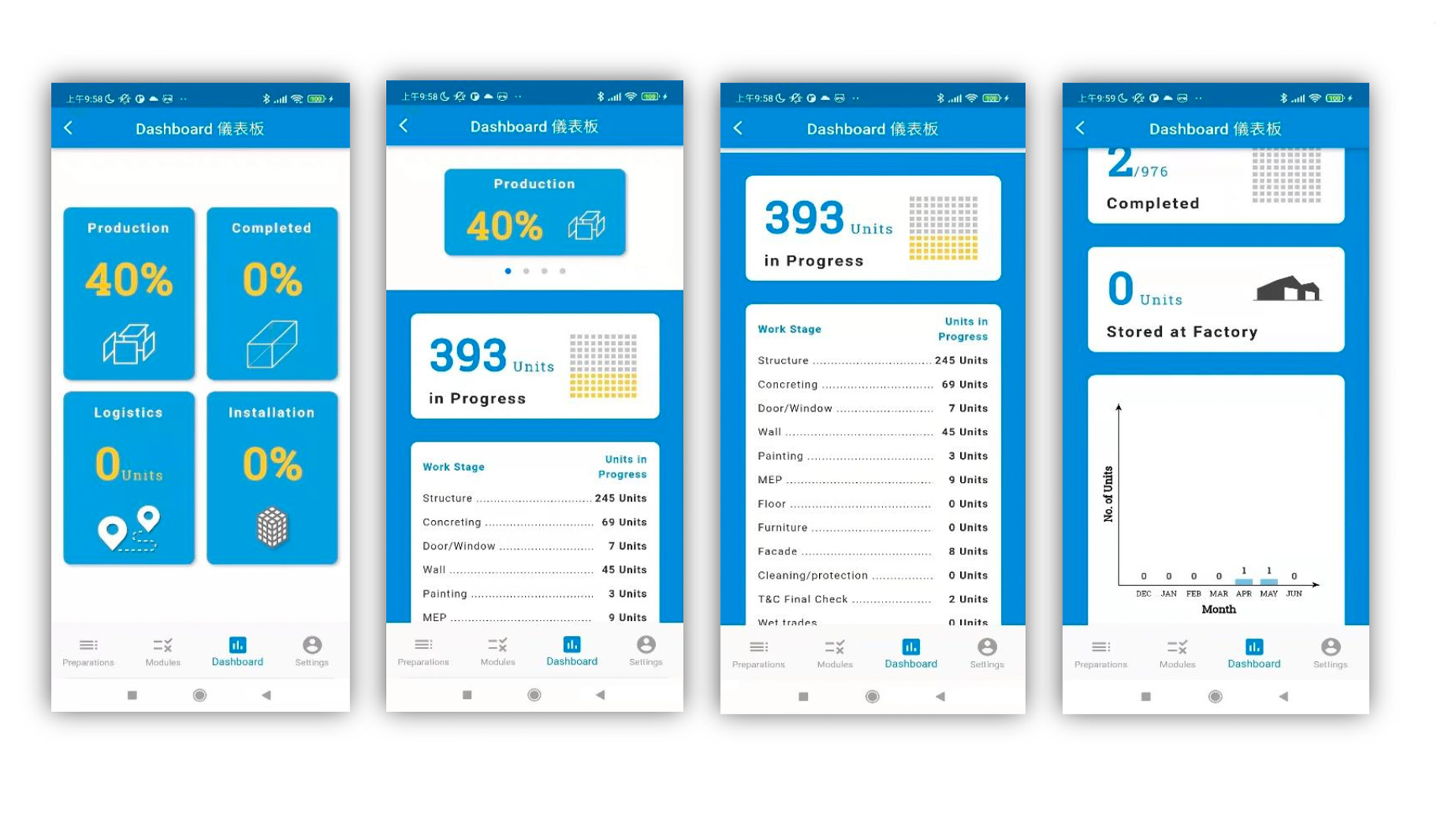

During the COVID-19 pandemic, sending authorized persons from Hong Kong to Mainland factories for onsite inspections was extremely difficult. That inspired the HKU research team to develop a new e-inspection 2.0 system. It consists of a mobile application called e-inStar which encodes the standardized inspection processes of MiC and enables inspection works in an offshore factory.

A breakdown of the e-inspection 2.0 process

- The contractor generates a list of inspection tasks for a specific project.

- Different stakeholders (e.g., registered structure engineer, authorized person) register on the platform and state their role types.

- A two-factor authentication (2FA) (i.e., password and fingerprint) will confirm the identity of the inspectors.

- When a construction task is completed, the contractor checks the target objects regarding the check items and records the corresponding data (i.e., inspection results and photos)

- At hold points, the client representative and/or registered structural engineer, authorized person, and building service inspector ask the contractor’s inspectors to recheck target objects under their real-time video supervision.

- The recheck results are compared with the record, and if they are the same and in compliance, the client representative and/or registered structural engineer, authorized person, and building service inspector can digitally sign the record in the distributed blockchain network.

- If any inconsistency or noncompliance is spotted, a request for re-inspection will be sent to the contractor. All records on procedures, being dispersed and stored in the blockchain network, are totally traceable.

- The signed record is converted into a legally effective document and stored in a distributed blockchain network. All records are thus immutable and safeguarded in the blockchain network.

The technologies used

“The core of the e-inspection 2.0 system is the blockchain technology which can ensure the accountability, immutability, and traceability of all the inspection information collected from the APP, IoTs, and GIS,” said Professor Lu.

Also, IoTs are utilized to collect temperature, humidity, vibration, and location information; GIS supports real-time proof of location, while BIM is used for better information management and presentation.

“We can instantly know the location, temperature, or whether the modules are damaged due to moisture or vibration etc. Each module will have its own ‘birth certificate’, which clearly records the details of each testing process and the persons responsible etc.,” said Mr. KL Tam. He hoped that the new system can be widely adopted to further drive innovation in the local construction industry.

The research findings have been published in the Journal of Management in Engineering, an academic journal of the American Society of Civil Engineers (ASCE). You can also download a slide presentation of the press event and watch a video demo of the e-inStar app.

Source and images: HKU, June 6, 2022

View the original article and our Inspiration here

Leave a Reply