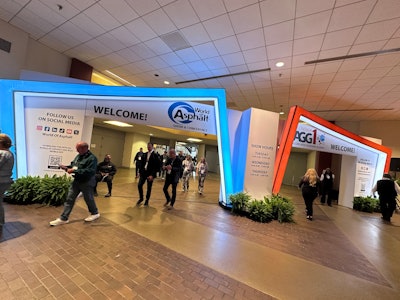

Here we are folks! This is the main event for the asphalt industry and it will be a full two years before we see the next World of Asphalt! It’s an exciting week, and we will be bringing all the latest news, products, events, and so much more every day.This will be your LIVE portal for asphalt pros who want to stay up-to-date during the trade show. Check back regularly for new updates, with the most recent positioned at the top of the page.

Consider this your World of Asphalt companion, and I, Brandon Noel, editor of Asphalt Contractor magazine, will be your guide!

First things first, if you aren’t subscribed to our bi-monthly newsletters, make sure you do that HERE!

The newsletters allow us to keep you up-to-date on the latest industry news year round, on live events like the INGITE Construction Summit and PAVE/X, as well as on our various contractor and equipment based annual awards.

3/27/25 – 2:09 PM CST

DAY 3: See You Next Time, World of Asphalt

Thank you, everyone for following along this week as we’ve been here covering the trade show! It’s been a busy, but still an amazing week for our industry. If you are just now finding this live-blog, then please scroll down and checkout everything we saw at World of Asphalt 2025.

3/27/25 – 1:25 PM CST

FAMC And My Continued Hunt For Automation

I tracked down the Flores Automation booth, wanting to find out from one of the top companies in the field of post-conversion automation solutions, what exactly their customers come to them looking for. It often times ends up being one of two things.

The first is a contractor who might for a solution that will make it easier to operate their pavers with a smaller or less-experienced workforce. The second could be someone who wants to upgrade an older piece of equipment and bring it up to the standards of a modern paver.

“[We] provides a solution called GT-1, it stands for Grade Tracer One. It is a 2d solution that serves as a 3d gateway that also can piggyback,” said Alexis Treace-Woodward, Regional Sales Manager-Southeast for FAMC.

Brandon Noel

Brandon Noel

“Take an old paver, say a 1990 paper that doesn’t have any plug and play ready. You take GT one, you put it on the back of that paver. That paver is now 3D ready,” said Woodward. “We take over the electric and hydraulic systems of that machine with GT-1. We install it, we tune, and test it, and then we can control the steering and paving [operations] too.

3/27/25 – 12:50 PM CST

CIVRobotics Looks To Disrupt Striping

Over the last few years, there have been a number of automation or robotics companies looking to disrupt the commercial side of the asphalt industry. This has taken the form of robotic cracksealing machines, a new startup is looking to make a sealcoating robot, and now a second company was to enter the pavement markings and striping arena.

CIVRobotics Business Development Manager Brandon Udelhofen explaining the striping robot to an attendee.Brandon Noel

CIVRobotics Business Development Manager Brandon Udelhofen explaining the striping robot to an attendee.Brandon Noel

My professional opinion is that if any space of the commercial pavement maintenance market is primed to be automated, and taken over by our future robotic overlords, it will most likely be the striping. Last year we spoke to 10Lines who also have an autonomous striping robot currently available, and I continue to see a common theme.

The biggest hurdle will be on-the-spot change orders. Whichever company can build a system with the easiest platform for designing layouts, that can also be quickly and easily adjusted on the day, will have the killer solution. Every contractor knows that you can come out, survey the site, go over the plans with the client, and still show up the day-of and be handed a surprise change order.

The CIVDash, robot stripier can layout 200′ per minute

• 8-hour battery life

• Mark points, dashes, and solid lines

• Layout at 3’/sec (1 m/sec)

It has a dual RTK receiver

• Sub-inch (2 cm) level precision

• Dual-antenna GPS-based heading

• IMU sensor for tilt compensation

• Connect to any local base station or NTRIP

• Follows GPS, GLONASS, Galileo, BeiDou

It’s also light and compact

• Weighs 35 lbs and fits in any vehicle

• Carry 2 extra spray cans

• Remote operation from safety truck

3/27/25 – 11: 04 AM CST

Vögele Pavers Are Primed For Automation

I’ve been really hunting the show for the outer limitations of machine automation. There are lots of different levels to the answer of that question. Firstly, the needs of the contractor or operators can drive the types of answers or solutions they should pursue. Secondly, the capabilities of their equipment, or the lack thereof, will also shape what possibilities are at their disposal.

With the SUPER 2000-3i VÖGELE has now developed an entirely paver for the North American market. The tracked SUPER 2000-3i is designed primarily for use in highway construction and large-scale commercial applications, which are all about power and productivity. With a powerful, 6-cylinder engine rated at 250 hp (186 kW) and high-output hydraulic drives, it is fully equipped for these jobs.

The Vögele Super 2000-3i paver is a behemoth of asphalt paving and comes ready for serious technology.Brandon Noel

The Vögele Super 2000-3i paver is a behemoth of asphalt paving and comes ready for serious technology.Brandon Noel

“In terms of automation, of controlling the machine’s depth, width, and direction; you need machine control [systems] for that,” said , Vögele’s paving product manager. “Your three top players [in that space] would be TopCon, Trimble, and Leica. “Most new projects today are designed with the model. So you can take that model, feed it into their system. Their system will tell us where we’re at and what our direction needs to be, what the width and the depth of the pavement, and then our machine control takes it from there.”

Vogele pavers have several key automation capabilities:

Machine Control

- Automated control of depth, width, and direction of paving

- GPS positioning instruments can read project models to guide machine positioning

Material Flow Automation

- Automated control of material flow to maintain consistent force

- Automated height control to ensure proper material placement

Software Integration

- Can directly communicate with positioning systems like Topcon

- Uses jump drive or similar method to transfer model data

- Allows seamless integration of positioning and machine control systems

However, there are a few barriers to what you might consider “full” automation in the paving space. They Still requires human oversight for setup, transportation, and monitoring. Humans are still needed to manage hydraulic systems, warm up equipment, and perform quality checks; not to mention, transportation to and from jobsites.

The current state of automation allows for precise control of paving processes, but complete autonomous operation is not yet feasible due to the complexity of interdependent systems.

3/27/25 – 9:49 AM CST

DAY 3: Before The Aftermath

Anyone will tell you that the last day of a trade show is very different from the others. It doesn’t matter if it’s PAVE/X, World of Asphalt, or CON-EXPO, which goes on for nearly a week, the final hours on the show floor can be….well, a ghost town. Some people have called it the “second show” because it’s a time where manufacturers get a chance to visit other booths themselves. There are chances for new relationships and partnerships between brands to spark up.

Brandon Noel

Brandon Noel

This is where we set our scene for today. I’ll be out here trying to capture as much as I can before the abbreviated day closes the show at 2:00 PM CST. If you’re still here, come on down and find me! We’ll be shooting for No Edge Lines content most of the morning.

3/26/25 – 5:12 PM CST

DAY 2: Over The Hump

We are headed into the endgame now! Day two has come to a close, and everyone is headed back to their hotels, dinner, and other industry events for the night. There is just one day left for World of Asphalt, but we will be back at it bright and early tomorrow morning with more live coverage.

Brandon Noel

Brandon Noel

3/26/25 – 4:44 PM CST

Blaw-Knox Stands By Legacy While Looking To The Future

Nearing the end of the second day here, but I wanted to make sure that I stopped by the Gencor & Blaw-Knox booth in order to get a better sense of what the vision for the company is going forward. I’ve only been in the industry a few years, and while I know that Blaw-Knox is a storied company, with a history spanning a century, since being acquired from Volvo CE, the question for me was if there were any big plans for the line-up in the near future. Especially with a CON-EXPO soon to come.

“We’ve made a number of changes and improvements and features changes to the pavers,” explained Marc Elliot, President and Director Gencor Industries. “[Blaw-Knox] is coming into its own. the whole concept behind the business plan was to put Blaw-Knox back into its own identity, its own products, its own designs, its own manufacturing and support network.”

Brandon Noel

Brandon Noel

Elliot further expressed that there are plans to start expanding the brand’s offerings into some paving support equipment, but he didn’t share any detailed specifics.

“We have plans to expand the name and the brand, and to other products beyond just pavers. Right now, it’s just fairly narrow with the paving products, but complimentary products are in our future. It’s awesome.”

Without giving too much away, Elliot said these support products could look like material transfer vehicles, road widening pavers, and other equipment that supports and belongs in a highway paving train.

“We want to advance the product in the areas that are beneficial to the contractors and the users,” Elliot said. “But we don’t want to over complicate the product to the users. Easy to work on, easy to maintain, and very dependable from all aspects. That’s our philosophy.”

3/26/25 – 3:13 PM CST

Getting Kind Of Dirty

I met a new friend on the show floor: Trey Bo Dirt. Do you know about Trey Bo Dirt? Well, he’s about the realist dude I’ve ever had the pleasure of filming a segment with for the series. He really tells it like it is, and he has a down to earth way about him.

He shared a little bit about his story, that he’d basically dropped out of school around the age of ten years old, and he’s been working practically ever since. A few years ago he started to gain an online following, and now has a fairly large following. As the two of us walked around the expo floor, we discussed contractors taking care of themselves.

Trey Bo Dirt (left) and Brandon Noel, editor (right).Pat Brown

Trey Bo Dirt (left) and Brandon Noel, editor (right).Pat Brown

Self-care for contractors isn’t as prominent a topic of conversation as a high tech new paver or roller. However, taking care of your business, your workers, and your family isn’t taking care of yourself. The contents of our whole conversation will be in the forthcoming first episode of No Edge Lines Season 3. Make sure you subscribe to our YouTube channel for every episode.

3/26/25 – 2:00 PM CST

I Believe In Green Asphalt

I first heard about the New York based makers of 100% recycled asphalt mixed in a YouTube video. Immediately, I was intrigued and curious about, not only their product, but their process. Shortly after, I visited their plant in the Empire State, and after Jim McMurray took me on a short tour I was completely sold. Here’s the rub: The national average for RAP usage hovers around 21%, but it also restricts the dumping or storage of RAP millings.

“New York mills-and-fills about a million tons of asphalt a year,” McMurray told me. “Only about 30% goes back into the roads, so every year you have nearly 700,000 tons of asphalt piling up. Some of it gets trucked away to other places, including some to Canada.”

It’s clear that the issue isn’t going to just go away.

Megan Perleberg

Megan Perleberg

The interview was recorded and will be released at a later time under a new “No Edge Lines” podcast banner. We talked about the significant progress they’ve made in drawing more attention and awareness to what they’re trying to do. After managing to offer NAPA Midyear Meeting attendees a tour of their facility and showing them a demonstration of their product, McMurray considered it one of their biggest wins.

While there are still a lot of detractors on the production side, the paving side, and the regulatory side, Green Asphalt and their team are still optimistic about the future.

“I think people have been watching and waiting to see if we would just peter-out,” said McMurray. “But we are here to stay.”

You can read more about the background of McMurray, Green Asphalt, and their mission here.

3/26/25 – 12:17 PM CST

Cimline Updates P2 Emulsion Based Pothole DuraPatcher

I’ve seen a lot of various equipment based solutions for fixing or patching potholes, since joining the industry three years ago. There are infrared solutions, cut-and-replace, cold patch, skin patch, mastic patches, and so on; and what stood out to me about this product was two things. First, the version on the trade show floor was the trailer based model, and it’s much more compact than you’d expect by looking at the picture.

Cimline’s P2 emulsion based pothole patcher, available in trailer form (seen here) and as a truck-mounted unit which can be operated by one worker.Brandon Noel

Cimline’s P2 emulsion based pothole patcher, available in trailer form (seen here) and as a truck-mounted unit which can be operated by one worker.Brandon Noel

I referred to the unit as a mini-asphalt plant on wheels, and the truth isn’t that far removed. Ben Thielbar, Director of Sales for Cimline, explained that the aggregates, coated with the emulsion go into a pothole at full compaction, requiring not external roller or plate compactor to achieve its finished status. In place of say, perhaps, a cold patch which will need to be ripped out and fixed once the winter months subside, a DuraPatcher P2 repair can last between two and three years.

When DOTs or commercial contractors are looking for fast solutions to roadway potholes, there are two main factors driving their equipment decisions. Safety and efficiency. For an added safety benefit, and an increase in efficiency, the P2 DuraPatcher can also be purchased as a rear-mounted truck unit, that’s capable of turning a single operator/driver into a one-person pothole patching machine. From the comfort and safety of the cab, they can make high quality repairs.

3/26/25 – 10:25 AM CST

Dynapac’s Updated Pneumatic Roller A 30-Ton Compaction Monster

It’s all in their name and compaction continues to be the sector of the industry where Dynapac continues to push forward the envelope for technology and quality. After debuting their new tack distributor truck at PAVE/X 2025, it has come to World of Asphalt with the brand new CP28 which can fine tune its weight to produce a more precise, quality compaction, and, as a result, improve the overall longevity.

The CP28 pneumatic tire roller, the largest in its class, capable of ballasting from 21,000 to 62,000 pounds. It features three ballast sections and water-sealed tanks. The roller is versatile, used in various applications like chip seal, soil compaction, and asphalt compaction in the “intermediate zone” temps between 180-220 degrees.

It offers static compaction, which differs from vibratory methods by exerting pressure from the bottom up, akin to kneading bread. New features include an operator station similar to other Dynapac models and an “air on the run” system for individual tire inflation and deflation.

3/26/25 – 9:47 AM CST

Dispelling The Fog Of War In Road Work

The Trimble MX-60 scanner is a data nerd’s dream, and its capability to gather up to 4 million data points is only the beginning. The scanner captures 360-degree data, including road conditions and features, creating rich point clouds for feature extraction and machine modeling. This data helps stakeholders, such as contractors and owners, with maintenance, bidding, and project management.

The Trimble MX-60 scanner.Brandon Noel

The Trimble MX-60 scanner.Brandon Noel

The system allows for real-time cost tracking and resource deployment, enhancing efficiency, and reducing errors. The platform’s interoperability with various systems ensures flexibility, and the technology aims to eliminate the “fog of war” by providing accurate, timely data, improving project quality and reducing potential legal risks.

5 Brief Takeaways From the MX-60 and the “Common Data” Trimble Ecosystem:

-

Comprehensive Data Capture – The platform allows for rich, 360-degree scanning that captures detailed point cloud data, including road conditions, infrastructure features, and environmental details, providing a complete digital representation of a project site.

-

Workflow Efficiency – The system streamlines the entire construction process from initial surveying to design, bidding, construction, and as-built documentation, reducing manual work and improving overall project productivity.

-

Interoperability – Trimble offers open APIs and compatibility with various systems and equipment, allowing users to integrate different technologies and data sources without being locked into a single ecosystem.

-

Real-Time Cost and Quality Tracking – The platform enables precise tracking of project progress, cost management, and quality control through detailed digital documentation at each phase of construction.

-

Digital Twin Creation – By capturing data at multiple stages of a project, the platform helps create a comprehensive digital twin that can be used for future maintenance, planning, and reference, reducing uncertainties and potential disputes in future projects.

3/26/25 – 8:40 AM CST

DAY 2: Exploration and Discovery

The energy and the excitement was all over every square inch of the trade show floor during the first day. People were everywhere, and the foot traffic was high just about everywhere you looked. I could felt the carrying power of adrenaline pushing me throughout the whole day. However, this is Day 2, and with the second day comes some of the “real work” of a show. People are settled in, they hit their top booths, and Day 2 becomes about the hunt.

Asphalt Contractor booth 3340 at World of Asphalt 2025.Brandon Noel

Asphalt Contractor booth 3340 at World of Asphalt 2025.Brandon Noel

People are going to wander into corners of the show they, perhaps, wouldn’t otherwise. Paving contractors might walk into a crushing booth. Milling contractors might checkout a crack sealing machine. Asphalt producers could find some new software they’d didn’t even know they needed. The point is that Day 2 is a wildcard, and the industrious attendee is getting out there, outside their “lane” and exploring what else our industry has to offer.

Stay tuned here for more great coverage, and if you’re at the show you can always stop by booth #3340 to see me!

3/25/25 – 4:57 PM CST

DAY 1: That’s A Wrap!

Hey, everyone! Thanks for an amazing, jam packed first day at World of Asphalt! I’ll be back and at it bright and early tomorrow, so make sure to come back and see what Day 2 has in store!

Brandon Noel

Brandon Noel

3/25/25 – 4:11 PM CST

CM Labs Adds Artificial Intelligence To Their Simulators

Some of you may know about my jobsite video series “No Edge Lines” where I’ve been doing my best to get out on real jobsites and learn how to operate the heavy machinery that makes our industry work. If you haven’t seen it yet, watch our latest episode here!

One of the biggest hurdles to my heavy machinery education is that I don’t have the opportunity to be out on jobsites regularly, which is the primary way that most people learn how to do things. CM Labs has been creating and refining a series of ever increasing complex simulators to solve this very problem.

Editor Brandon Noel sits in the CM Labs multi-use simulator that was setup for excavator training, but can simulate 20 different machines.Pat Brown

Editor Brandon Noel sits in the CM Labs multi-use simulator that was setup for excavator training, but can simulate 20 different machines.Pat Brown

I did my best to operate the simulator and complete a training module designed for digging one six-foot trench. I wasn’t able to even complete 5% of the task before I found myself struggling.

The reps from CM Labs explained that difficulty and, yes, even boredom are intentional factors built into the training. They don’t want it to be “fun” and they don’t want trainees to be entertained by the simulation, they want it to truly reflect what it’s like to be on the job. While it may have the look of a high tech video game, it’s truly an educational tool.

For any company or trade school looking for a smarter, more cost effective way to bring new-hires and students up-to-speed on the fundamental operations of heavy machinery, then simulators like these are a smart choice. Additionally, we tested out the new AI training assistant that is currently in a prototype or beta-testing phase.

Pat Brown

Pat Brown

When I asked if it could explain how to turn on the machine, not only did it walk me through the process, but it also advised me on additional safety precautions that I should be aware of in the scenario. This was something that I found to be most interesting. Rather than just dumping the most basic information on me regarding my question, the AI trainer treated me like a true novice who wouldn’t be aware of the safety concerns otherwise.

I think AI-powered simulators like these could go a long way to filling in the gaps between labor needs and a lack of time, qualified educators, and resources.

3/25/25 – 3:03 PM CST

BOMAG Wants You To Know Their Pavers Mean Business

Last year the BOMAG CR 1030 T was named to the Pavement Maintenance Top 25 Products List for the impressive upgrades the company brought to the table for their flagship paver. This year they’re working on extending some of those same upgrades to its sister paver the CR 820 T2 and more. Asphalt Contractor stopped by their booth to take a closer look at all that’s new. Read more below.

The CR 820 T2 and CR 1030 T from BOMAG.Brandon Noel

The CR 820 T2 and CR 1030 T from BOMAG.Brandon Noel

Here are 10 quick takeaways from the BOMAG Paver Updates conversation with Jon Elko, Senior Business Development Manager at BOMAG, which you can read in full detail HERE:

1. Universal Frame Raise Design: BOMAG has developed a new frame raise unit that allows individual control of auger conveyors, enabling left and right material feeding.

2. Advanced Technology Integration: The new paver features MOBA system, HMI display, and Topcon compatibility, providing enhanced technological capabilities.

3. Segregation Solution: BOMAG eliminated center line segregation by positioning chain cases on the outer sides of the conveyor, with a central bearing.

4. Improved Screed Ergonomics: The new front mount screed features two-finger control, raised height for operator comfort, and quick-response coarse thread screws.

5. Extensive Width Capability: The new paver can handle up to 20-foot paving width, utilizing proven tubing systems from Fayat’s Italian engineering team.

6. Serviceability Focus: The design maintains BOMAG’s commitment to wear components, with easily rebuildable panels and a simple 12-volt system.

7. Sonic Sensor Technology: The paver includes sonic sensors on both sides to control mix height and volume, improving precision.

8. Ergonomic Control Design: The steering wheel and control layout are designed for multitasking, with interchangeable toggle and rocker switches.

9. Heavyweight Performance: The screed weights start at 7,000 and can go up to 9,300 pounds, ensuring a smooth, “buttery” paving surface with minimal imperfections.

10. Modern Technology Emphasis: BOMAG is positioning these updates as a response to industry demand for more integrated, user-friendly technological solutions.

3/25/25 – 1:34 PM CST

Ammann’s Big Plans For North American Market

Over the last few years, Ammann has been making serious moved behind the scenes in the North American market, including relocating their headquarters to a more central east cost location to better serve their growing customer base. While they couldn’t fully reveal all the details at this time, Asphalt Contractor was able to learn that Ammann has three forthcoming asphalt plant projects to be made public soon. This includes a new focus on batch plants and facilitating a paradigm shift on how the decades old technology has undergone major improvements.

Ammann America’s World of Asphalt 2025 booth.Brandon Noel

Ammann America’s World of Asphalt 2025 booth.Brandon Noel

However, Ammann’s ambitions are not limited to the production side of the industry. Near the end of 2023 they made a deal to acquire the ABG line of pavers from Volvo, and, now, they are poised to make a renewed push into the United States highway-class, high-density paving market. There are a limited number of North American manufacturers who offer asphalt pavers capable of high-density, heavy lift paving, more common in the European space.

“Our current strategy for ABG [in North America] is strictly in the rolled concrete (RCC) or projects that require high-density lifts,” said Iulian Neacsu, ABG Paver Sales and Support Manager at Ammann America.

Ammann believes that the winds of change could shift in their favor.

“Every job that requires high density: airports, ports, or [certain] highway projects,” Neacsu continued. “Most of the pavers that you see, they are not real builders. They are maintainers. They are pavers designed to put between two-and-four inches of asphalt at high speed with a large number of compactors behind. Our advantage with the high density grid, single temper or double tamper, is that we reduce dramatically the number of rollers behind the screed.”

What has been considered for many years the “Euro-style” of paving, slow and deep lifts of asphalt, has seen somewhat of a resurgence in the U.S. although in fairly niche applications.

Neacsu commented that with a potential trend in infrastructure investment shrinkage on the state level, highways and other roadway pavements with longer useable lifecycles may see an uptick in prioritization.

“Until now, we harvest pretty much the asphalt every two or three years, and we put it back,” Neascu said. “If you want to increase the lifespan of the roads up to seven or ten years, you have to use the tamper bar methods. There’s no shortcut to it.”

3/25/25 – 12:21 PM CST

World’s First Skid Steer Center Paver

The CP1000 minimizes material wastage and eliminates laborious hand work. With a wireless remote-control system and built-in cameras for precision, this paver handles various thicknesses and widths effortlessly. Plus, its design significantly reduces both capital and maintenance costs compared to single-use equipment.

Click here to read a more in-depth Q&A with ShoulderMaster about their amazing new product!

- Designed by the industry for the industry

- Lays asphalt and gravel materials

- Chain driven, heat rated belt to withstand asphalt

- Wireless remote control for operator safety

- Wireless camera with in cab monitor for ease of operation

- Screed width from 12.5″ to 40″

- Screed dropping below existing pavement of 0″ and 4″ above at any width allowing precisely place materials in multiply layers

- Hopper capacity 88 ft3

- Universal skid steer attachment

- Built tough to withstand harsh conditions

3/25/25 – 10:45 AM CST

Volvo CE Debuts The A50, New Rollers, And More!

Here at the Volvo CE Press Event, Scott Young, head of the North American region at Volvo CE, talked about products like the A50, making its North American Debut! Young also discussed a large wheel loader and several new rollers in the lineup including the new DD15 electric tandem roller.

3/25/25 – 8:41 AM CST

We are off to the races this morning! The show floor will open to the public in less than twenty minutes, and then there will be a stream of updates all day long! Let’s take a look at my day, and you can follow along, or, if you’re here at the show, meet up with me at a booth! Make sure to check back regularly throughout the day for these times and events below, and much more!

Day 1: At A Glance

- A visit with Portable Lighting Solutions @ 9:00 AM CST

- PRESS EVENT: Volvo CE @ 10:00 AM CST

- WORLD REVEAL: ShoulderMaster’s new paving skid steer attachment!

- Touring the aggregates hall

- PRESS EVENT: Wirtgen Grooup @ 2:00 PM CST

- A visit to CM Labs booth @ 4:00 PM CST

3/24/25 – 10:51 PM CST

Raised On Blacktop X World Of Asphalt Kickoff Party

Everyone knows that when the Raised On Blacktop crew puts together a party, it’s gonna be a BIG one. This year was one of the biggest pre-show parties ever, and at one of the coolest venues too.

Busch Stadium, home of the St. Louis Cardinals.Brandon Noel

Busch Stadium, home of the St. Louis Cardinals.Brandon Noel

This year’s kickoff event was held at Busch Stadium, the home of the St. Louis Cardinals Major League Baseball team. Sponsored by Portable Lighting Solutions, LeeBoy, Wirtgen, X-Broom, and others, the partygoers were treated to live music, food, and drink all in the RedBird Club.

While everyone was having a great time, there was a huge sense of excitement as everyone was looking ahead at the asphalt industry’s biggest annual trade show.

If you’re coming down to St. Louis this week, make sure stop by and say hello at both #3340!

Entrance to the. RedBird Club.Brandon Noel

Entrance to the. RedBird Club.Brandon Noel

3/24/25 – 12:03 PM CST

LET’S GOOOO!

Everyone is loading in and getting their booths set up for tomorrow’s main event!

View the original article and our Inspiration here

Leave a Reply