New products are introduced to the general equipment and tool rental industry all the time. Whether these are announced as an updated solution, a brand new tool, or new equipment to add to your lot, these products found a problem and have been designed to address it.

As published in the March/April 2025 issue of Rental.

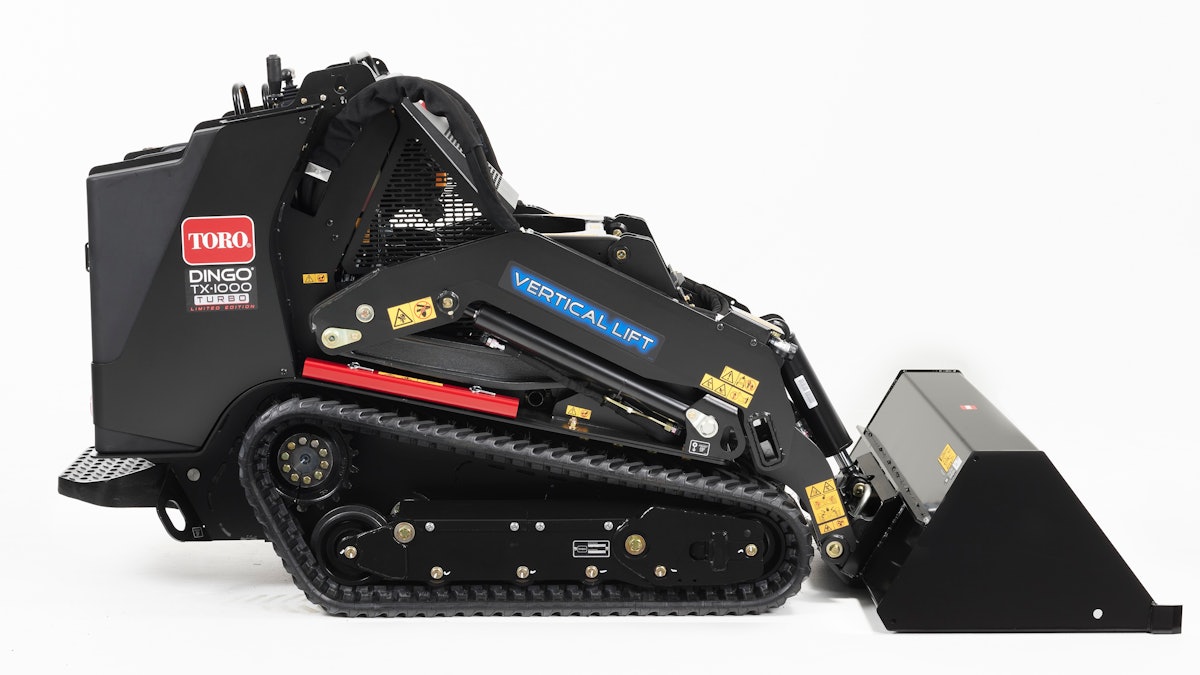

The Dingo TX 1000 TURBO, for a limited time only, will be available in an exclusive, textured matte black finish – offering a bold new look that matches its unmatched capabilities. The release of the Dingo TX 1000 TURBO Limited Edition coincides with the 10th anniversary of the Dingo TX 1000, the compact utility loader that changed the trajectory of the equipment category with a rated operating capacity of 1,000 lbs. The Dingo TX 1000 TURBO is the next stage in that legacy with a turbocharged Yanmar diesel engine and the new patent-pending Smart Power feature to maximize engine, auxiliary and traction torque. The Dingo TX 1000 TURBO’s new turbo diesel engine delivers increased torque, boosting productivity when using attachments such as the trencher and auger.

Loftness has expanded its line of Battle Ax mulching heads with the new 10 Series. Featuring a lightweight, yet heavy-duty design, it can be used on smaller excavators ranging from 7,000 to 10,000 lbs. in a variety of applications. The depth gauges, which function like raker teeth on a chain saw, optimize the amount of material being fed into the drum at one time, resulting in easier operation, faster production, and more desirable particle sizes.

Additionally, the 10 Series includes the exclusive Loftness two-stage cutting chamber, which uses two shear bars to help process material more thoroughly. The 10 Series Battle Ax is powered by a 45cc fixed-displacement gear motor, which requires 20 to 70 hydraulic hp and 15 to 35.9 gpm hydraulic flow to operate. It has a 25-in. cutting width and overall weight of 620 lbs., depending on options, making it compatible with many popular models of compact excavators.

Customers can choose between three types of cutting teeth: reversible planer teeth, four-point beaver teeth, or double-carbide teeth. The teeth are mounted to the rotor with a single bolt, so they can be easily reversed or replaced on the jobsite using a common hex socket. They are arranged in a staggered/spiral pattern that ensures optimal rotor balance while maintaining single-tooth contact with the work surface at all times. Other available options include a spade hook for helping position material to be mulched.

MGT America launched of its new Poly Drum line, featuring the Mortar Mixer, Cement Mixer, and Wheelbarrow Mixer. These products were designed with rental businesses in mind and offer a durable, efficient, and lightweight solution that meets the unique needs of high-turnover rental operations. The Poly Drum line was engineered to support rental companies looking for equipment that stands up to frequent use and diverse site conditions. Key benefits of these poly drum products include:

- Poly drums resist corrosion, significantly lowering the maintenance needs of equipment subjected to multiple users and jobsites. This durability enhances the drum’s lifespan, maximizing rental businesses’ return on investment (ROI).

- The lighter poly drum makes it easier for a broad range of users to handle, reducing strain.

- Poly surfaces prevent cement from adhering as firmly as it does to steel, allowing for faster, easier cleaning.

- Poly drums reduce noise, making these mixers ideal for residential and noise-sensitive jobsites.

- Lightweight poly drums reduce fuel usage during transport.

- Poly drums offer customization options, allowing rental businesses to brand their equipment.

KEG’s vibrating rotational nozzle is called the Duce Nozzle. The rotating nozzle, which is available for rental, can be particularly effective for removing hardened deposits on the floor or wall of sanitary sewer and storm lines. The special nozzle utilizes water driven rotation and vibration to create a unique “jackhammer” action to remove difficult materials such as scaling, grout/mortar residue, tuberculation, or other deposits within pipes. This approach is safer, faster, and more efficient than cutting and milling out the material. The Duce is specifically designed to remove deposits that have hardened to the pipe wall or floor such as grout, and mortar residue. KEG Technologies’ Duce Nozzle works extremely well to break up hardened debris.

When water conservation is necessary, KEG offers another version of the Duce Nozzle that is purposely designed to be used with recycled water and a recycling truck. The use of a recycling truck facilitates up to 5 more hours of jetting per day since the work crew does not need to retrieve more water every 15-20 minutes. The approach saves water, fuel, and vehicle/machine wear.

The New Holland Construction landscape rake was designed to remove small to medium-sized rock as small as 3/4 in. along with unwanted roots and debris.

- Picks up material as small as 3 to 4 in.

- Adjustable side skids for setting depths

- Exclusive replaceable bolt-on rake bars

- Rake bars scarify and level while breaking up lumpy soil and picking up rocks

- Dual springs on cover allow for adjustable down-pressure

- Top cover opens hydraulically for easier dumping

- Plug and Play Ready: Includes proper hose lengths, quick disconnects, wire harness, and universal mounting plate

Genie

Genie

Genie announces an all-new, future-focused design for its core slab scissor lift product line that further improves performance and lowers the total cost of ownership for Next-Generation Genie GS-1932, GS-2632, GS-3232, GS-2646, GS-3246, and GS-4046 scissor lifts. The most noticeable change with the next-generation slab scissor lifts is the curved linkage design. This departure from industry standard reduces machine weight, allowing Genie to use right-sized components—including batteries, drive motors and other electrical components—which have a lower replacement part cost. Genie benchmarked its new lifts against competitors’ machines, and our own E-Drive scissors, to ensure industry-leading performance. Other intentional design changes also improve quality and add to cost savings. These changes are the result of an extensive analysis at the beginning of Genie’s design process to identify opportunities to eliminate rust, limit the opportunity for damage, and reduce wear and tear. For example:

- It’s common for water to pool at the top of machine chassis, resulting in rust. Genie designed its new chassis to mitigate stagnant water in these areas.

- Extension decks can be damaged or bent during use; Genie added reinforcement steel in targeted locations to reduce damage.

- During loading and unloading, operators occasionally mis-fork the side pockets, causing damage to the chassis and swing out trays. Genie added steel around these side pockets to reduce the chance for damage to the chassis.

View the original article and our Inspiration here

Leave a Reply